- Bonder & Flip Chip

- Atmospheric Plasma Cleaner

- Vacuum Plasma Cleaner

- Spin Rinse Dryer

- Dispensing & Micro/Nano Printing System

- Lithography Process Systems

- Diffusion and LPCVD Furnaces

- Rapid Thermal Processing & Annealing

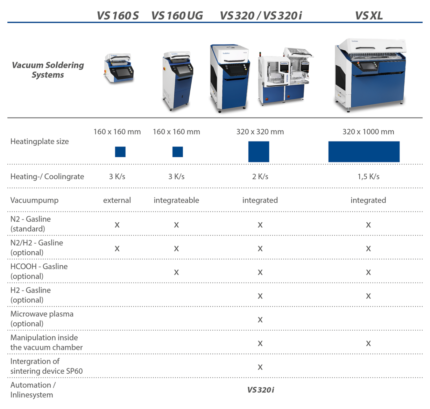

- Vacuum Soldering Systems

- Parylene Coating System

- Deposition System

- Hollow Cathode Plasma Source

- Plasma Etching System

- Sintering Presses

- Wet Process & Plating Tool

- Vacuum Chamber

- Electron Beam & Photo Resist

- Deposition Materials

Thermocompression Bonder

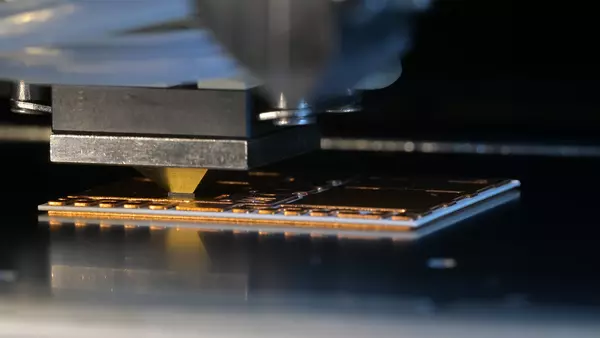

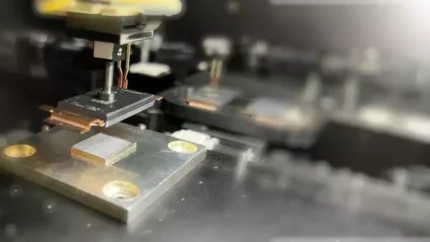

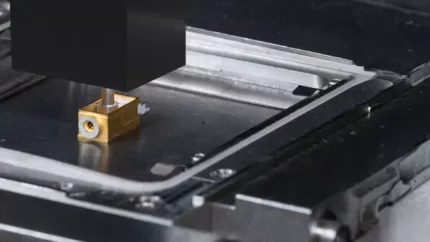

Thermocompression bonding, also abbreviated as TC bonding, is a process in microelectronics and microsystems engineering used to bond devices, especially semiconductor chips, to substrates or other assemblies. This process takes place in Tresky’s thermocompression bonders using heat and pressure to create a permanent bond.

Category: Die Bonder

Tags: chip-to-chip, die bonder, optoelectronic, RF device, semiconductor, TC bonding, thermocompression bonder

Description

Precision Process for Material-Locking Connections in HF and Optoelectronic Applications

Thermocompression bonding is an electrically conductive, mechanically strong and flux-free joining process. Similar to diffusion bonding, a stable, material-locking connection with very good electrical conductivity is created. In many cases, TC bonding involves placing a flip chip of gold or indium, for example, on a substrate with pads. By applying force and temperature over a defined time and, if necessary, plasma activation, the bond is formed.

TC bonding is particularly suitable for RF and optoelectronic devices, chip-to-chip and chip-to-wafer applications. Typical alloy compounds to be mentioned here are Au-Au and Au-Si.

Throughout the process, parameters such as temperature, pressure and time must be carefully controlled to achieve the desired results. The choice of materials is also critical to achieve the desired properties of the compound.

Added Value

Good Electrical Properties

Connections made by thermocompression bonding have excellent electrical properties because the process provides high contact quality and low electrical resistance.

Precise Alignment

By using positioning and alignment techniques, a very precise connection can be achieved.

Good Thermal Conductivity

Heat transfer properties are generally good, which is important for component cooling.

Reliability

Thermocompression bonding can produce reliable and durable connections.

Miniaturization

Thermocompression bonding enables miniaturization of electronic components and contributes to the development of compact and high-performance devices.

High Throughput Rates

Thermocompression bonding is a fast process and enables high throughput rates in mass production of semiconductor devices.

Variable Parameters for TC Bonding are

- Bonding force (pressure)

- Temperature

- Bonding time