- Bonder & Flip Chip

- Atmospheric Plasma Cleaner

- Vacuum Plasma Cleaner

- Spin Rinse Dryer

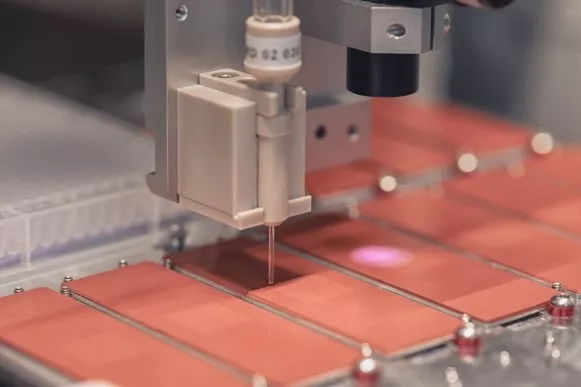

- Dispensing & Micro/Nano Printing System

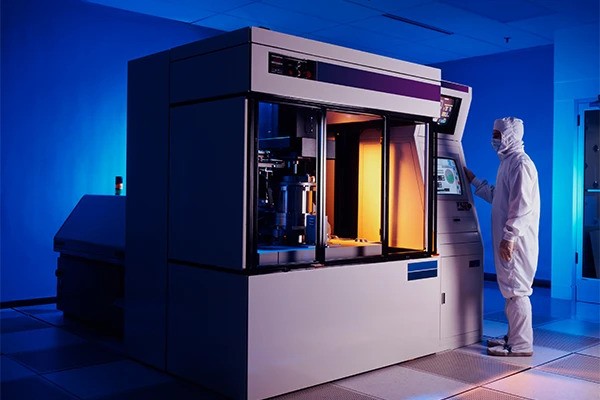

- Lithography Process Systems

- Diffusion and LPCVD Furnaces

- Rapid Thermal Processing & Annealing

- Vacuum Soldering Systems

- Parylene Coating System

- Deposition System

- Hollow Cathode Plasma Source

- Plasma Etching System

- Sintering Presses

- Wet Process & Plating Tool

- Vacuum Chamber

- Electron Beam & Photo Resist

- Deposition Materials

Packaging Applications

Die Bonder - Tresky

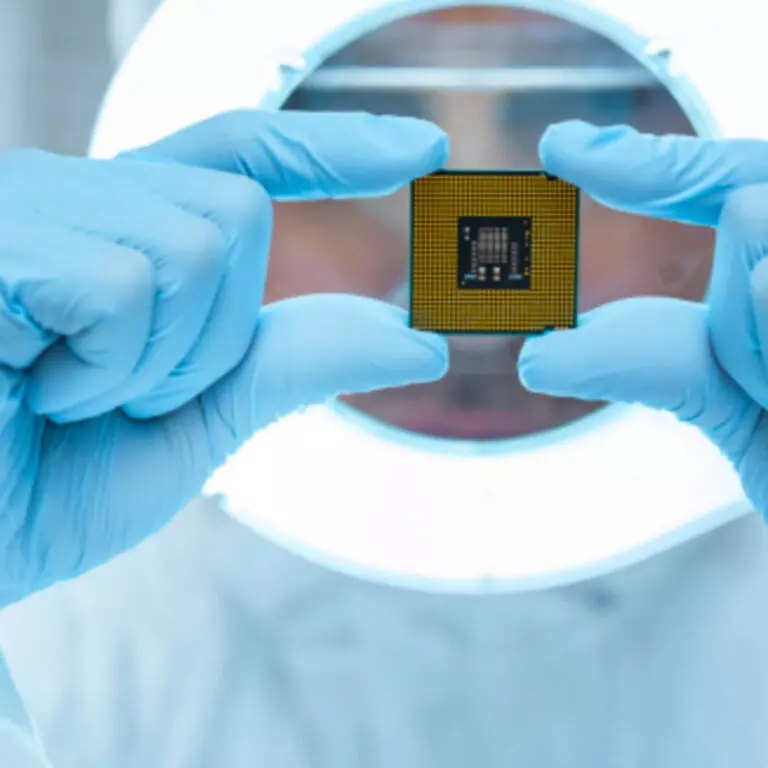

Semiconductor Industry

DIE bonding is a key process in the manufacture of integrated circuits (ICs) and microchips. Using different bonding solutions, DIEs are placed on substrates, ensuring that they are correctly connected electrically and mechanically.

Die Bonder - Tresky

Electronics Manufacturing

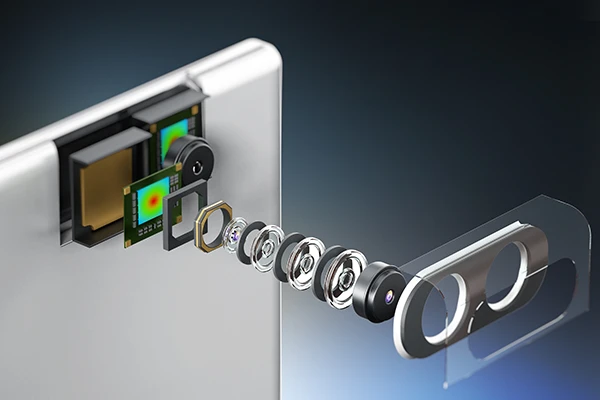

In the electronics industry, DIE bonding is used to assemble semiconductor chips in various electronic devices and assemblies. This includes applications in cell phones, computers, televisions, cameras and many other electronic products.

Die Bonder - Tresky

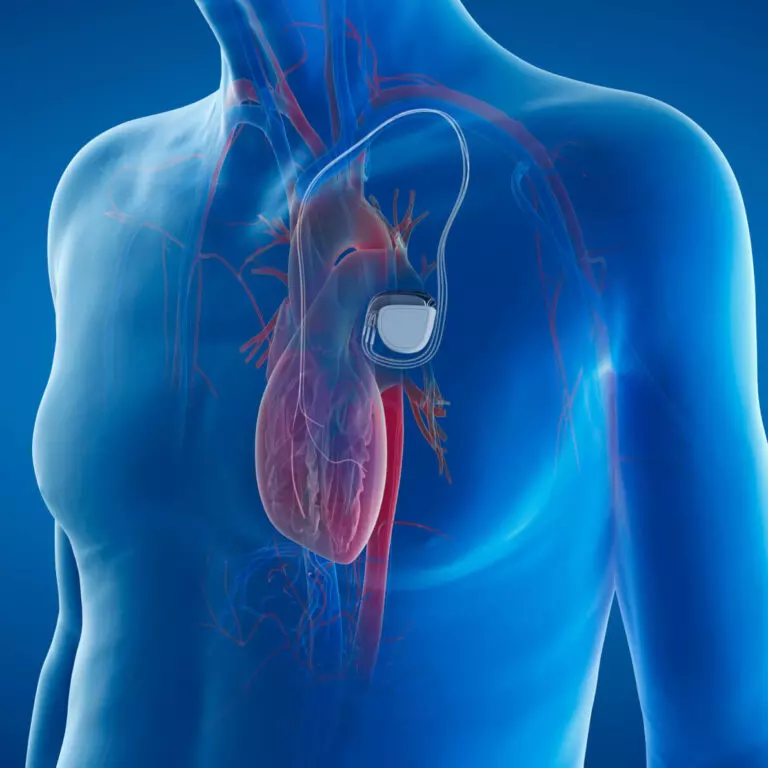

Medtech

DIE bonding is also used in medtech to produce compact and reliable electronic assemblies for medical devices such as implantable pacemakers, diagnostic equipment and medical imaging systems.

Packaging Applications

Die Bonder - Tresky

Aviation and Aerospace Technology

In the aviation and aerospace industry, electronic assemblies and components are often exposed to extreme conditions. Reliable DIE bonding is therefore of great importance to ensure that the electronics also operate under extreme temperatures and vibrations.

Die Bonder - Tresky

Optoelectronics

In optoelectronic applications, such as optical communication systems and laser diodes, DIE bonding is used to mount optoelectronic components and ensure that they are precisely aligned.

Die Bonder - Tresky

Sensors

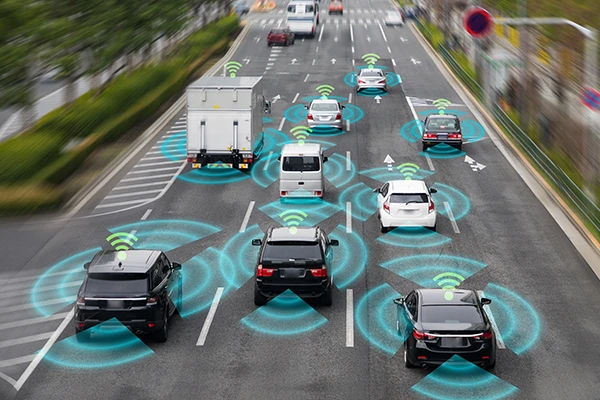

The production of sensors used in a wide range of applications often requires DIE bonding to securely position the sensitive sensor elements on the substrate.

BioTech Applications

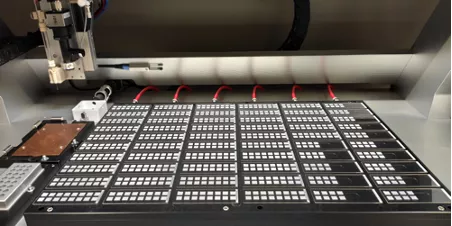

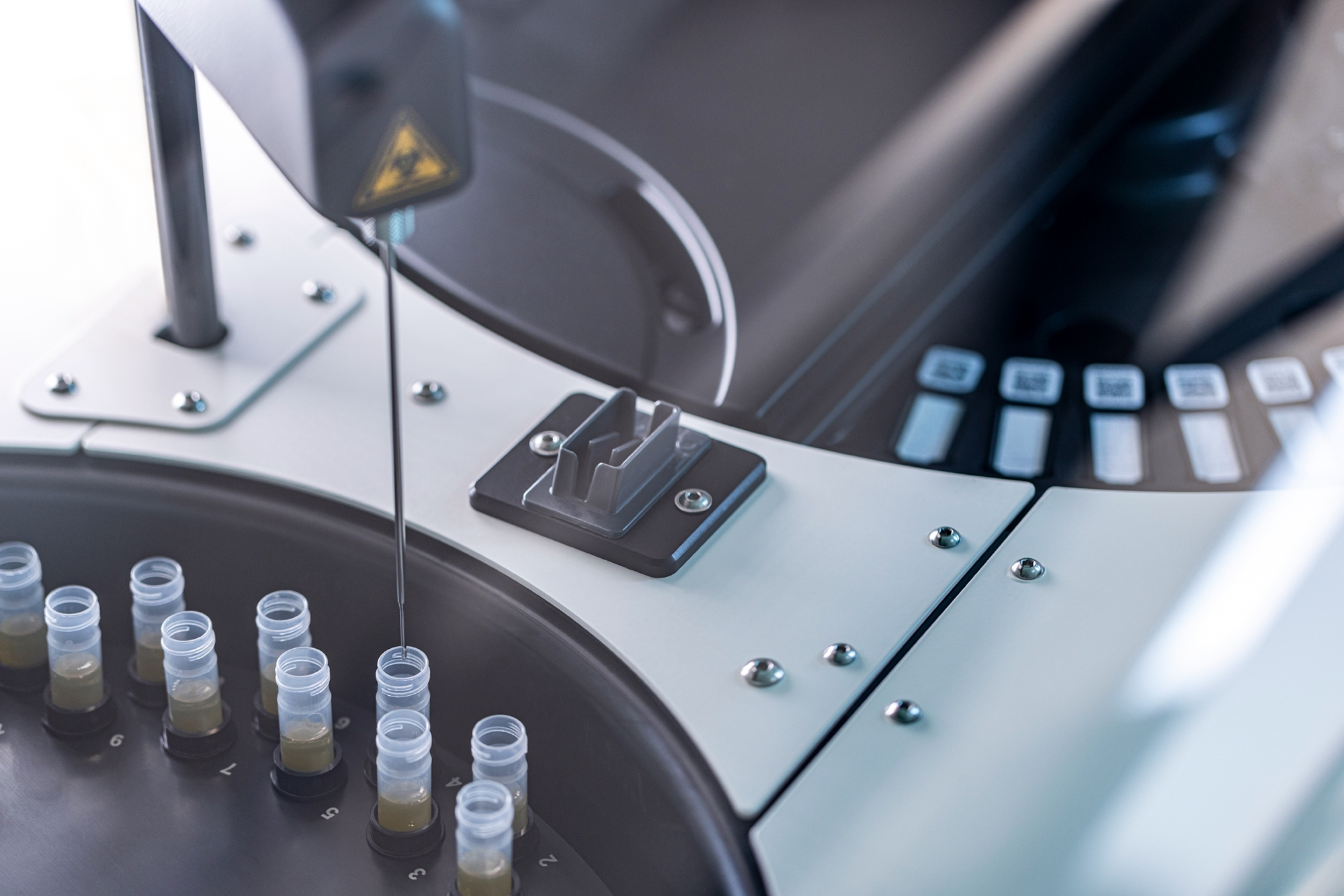

Microdispenser - M2 Automation

Genotyping for Antimicrobial Resistance

M2-Automation’s iONE-1200 is used by INTER-ARRAY® to produce a DNA microarray printed on the bottom of each well of 96-well plates on a production scale.

Microdispenser - M2 Automation

Mass Sensitive Micro-Array (MSMA)

Biomensio, located in Tampere, Finland, has developed a powerful, fully digital, mobile multianalyte biosensing platform, consisting of a fluidic cartridge, a mass sensitive microarray (MSMA), and a handheld reader, which is operated by embedded software.

Microdispenser - M2 Automation

TCR(m) Drug Development in Immune-Oncology

The instrumentTWO from M2-Automation works hand in hand with BioCopy’s cutting-edge technology for the fabrication of high-quality microarrays.

BioTech Applications

Microdispenser - M2 Automation

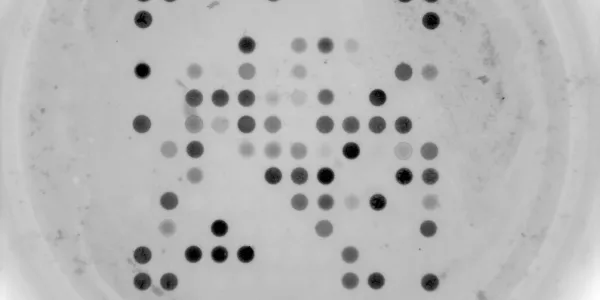

Quantitative Assay: Protein Microarray

Protein microarrays are microscope slides, printed with thousands of tiny spots in defined positions. They allow for rapid, economical and automated handling of highly sensitive materials, and they were developed due to the limitations of using DNA microarrays for determining gene expression levels in proteomics.

Microdispenser - M2 Automation

Real-Time Nano-Sensing for Continuous Multi-Metabolite Monitoring

QuLab Medical Ltd, a medical technology company based in Tel Aviv, enables personalised metabolic profiling through their diagnostics and biosensor technology.

Microdispenser - M2 Automation

Protein Microarray Dispensing of Bead Solutions

MADx established a protein microarray based on 300 different bead solutions coated with different allergens. These solutions are dispensed by several instrumentONEs within a 3 x 1.8 cm membrane format (cartridge) using a customized 3-channel nanoliter dispenser.

BioTech Applications

Microdispenser - M2 Automation

Biosensor functionalisation

AIT Austrian Institute of Technology is equipped with state-of-the-art non-contact liquid handling systems such as the M2-Automation iONE-600 dispenser.

Microdispenser - M2 Automation

The Droplet Microarray

Aquarray, a German biotech company, is developing a proprietary technology platform, the Droplet Microarray (DMA), which enables highly miniaturized assays, screenings and analyzes.

MedTech Applications

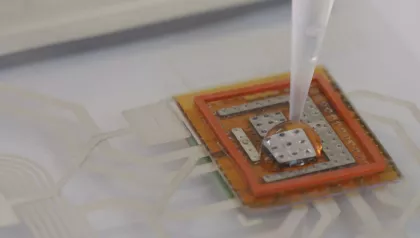

Microdispenser - XTPL

Medical device microelectronics

The integration of microelectronics in medical devices enables accurate diagnoctics, real-time monitoring, minimally invasive procedures, and improved patient outcomes. The continued advancement of microelectronics will further enhance the capabilities and applications of medical devices.

Microdispenser - XTPL

Implantable medical devices

The microelectronics medical implants market, focusing on product, application, and material segments, provides insights for identifying key market applications. Product segmentation includes pacemakers & defibrillators, neurostimulators, implantable drug pumps, and spinal fusion stimulators. Material segmentation covers metals, polymers, and ceramics, offering a concise overview for strategic decision-making in core market applications.

Microdispenser - XTPL

Wearable health monitoring devices

Devices like fitness bands and smartwatches utilize microelectronics to monitor physical activity, heart rate and sleep patterns; Continuous Glucose Monitors (CGMs) – to provide real-time data about glucose; smart ECG monitors – to detect irregular heart rhytms and provide early warning signs for cardiac issues.