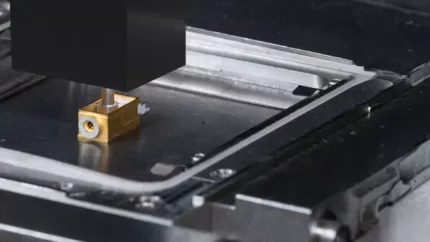

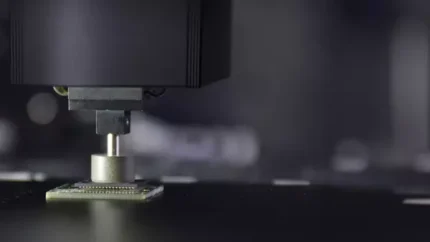

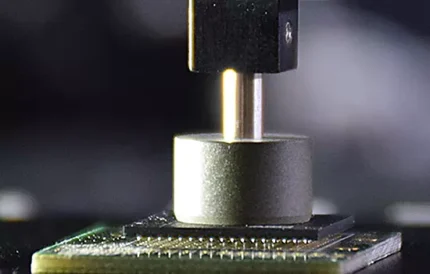

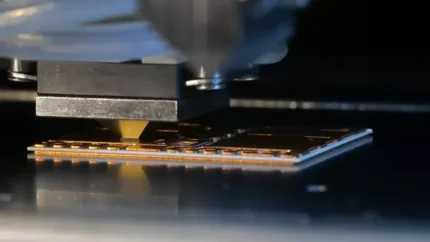

- Bonder & Flip Chip

- Atmospheric Plasma Cleaner

- Vacuum Plasma Cleaner

- Spin Rinse Dryer

- Dispensing & Micro/Nano Printing System

- Lithography Process Systems

- Diffusion and LPCVD Furnaces

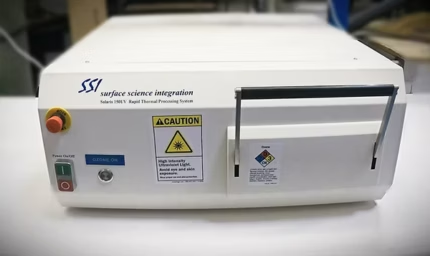

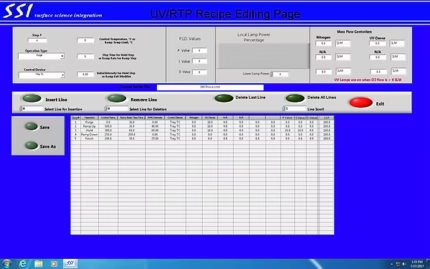

- Rapid Thermal Processing & Annealing

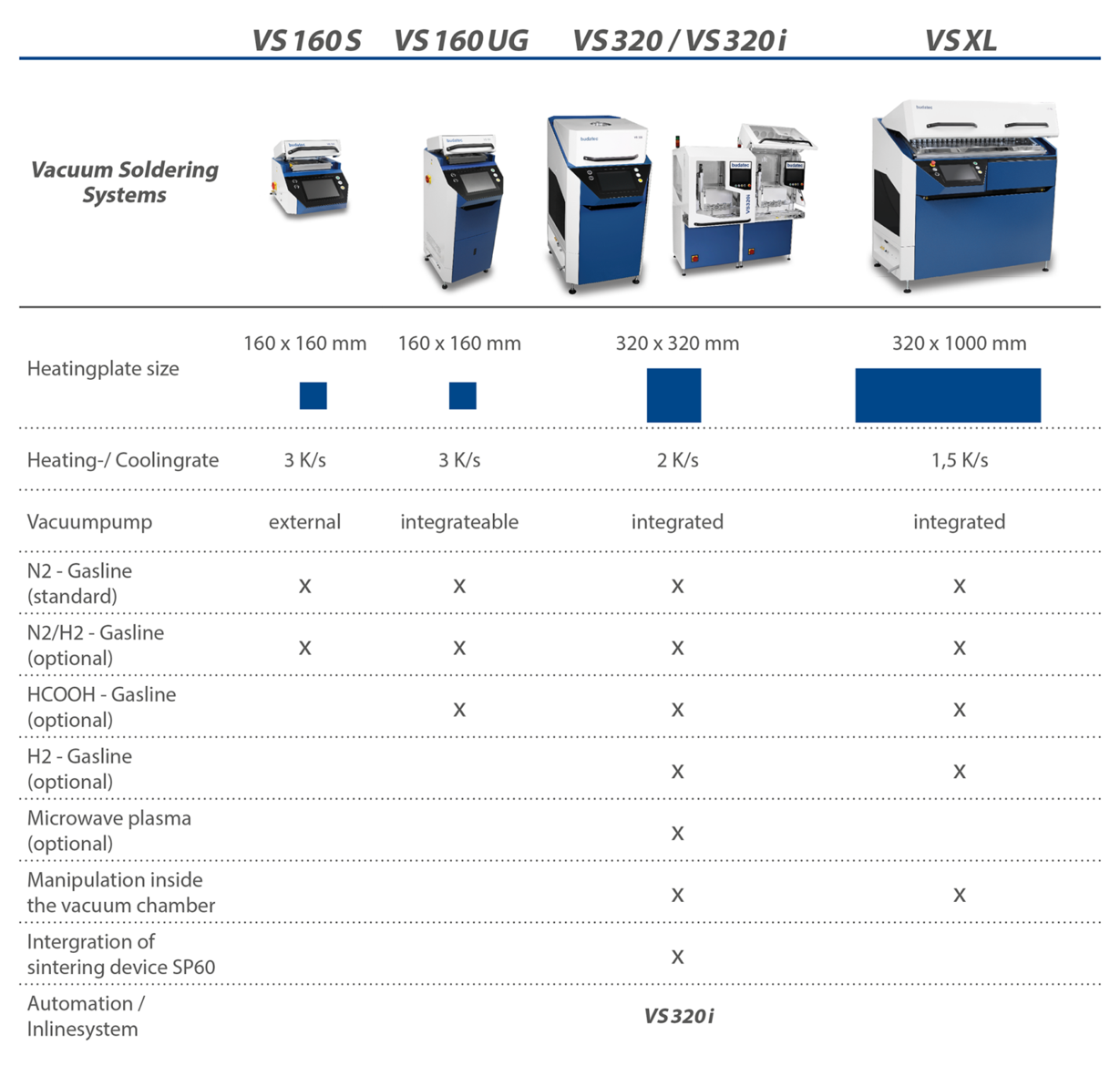

- Vacuum Soldering Systems

- Parylene Coating System

- Deposition System

- Hollow Cathode Plasma Source

- Plasma Etching System

- Sintering Presses

- Wet Process & Plating Tool

- Vacuum Chamber

- Electron Beam & Photo Resist

- Deposition Materials

VS XL

The VS XL vacuum soldering system can be used for processing large parts and large batches due to the heating plate size of 1000 mm x 320 mm.

In addition to the available options hydrogen (concentration adjustable up to 100 %), HCOOH and special gases as well as motor-driven manipulators can be integrated within the workspace

Category: Vacuum Soldering Systems

Tags: Budatec, semiconductor, soldering

Description

Technical Data

Plate size: 1000 x 320 mm2

Chamber height:100 mm

Max. soldering temperature: 350 °C

Heating- / Coolingramp: 1,5 K/s

Max. load: 45 kg

Process atmosphere: N2 / N2H2 (95/5) / HCOOHPower supply: 400 V / 64 A

Cooling Water: 20 slm

Features

- Process-Control via separate thermocouples

- Graphical overview of process components

- Digital manual integrated in the software

- Maintenance reminder

- Proposal for changing necessary components at the end of lifetime

- Power monitoring to detect defective heating rods

- Monitoring of energy consumption (Industry 4.0)

- Optional manipulation inside the chamber

- Optional MES protocol: SECS/GEM, OPC-UA, etc