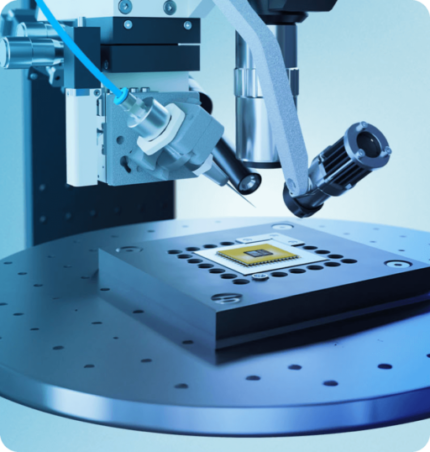

- Bonder & Flip Chip

- Atmospheric Plasma Cleaner

- Vacuum Plasma Cleaner

- Spin Rinse Dryer

- Dispensing & Micro/Nano Printing System

- Lithography Process Systems

- Diffusion and LPCVD Furnaces

- Rapid Thermal Processing & Annealing

- Vacuum Soldering Systems

- Parylene Coating System

- Deposition System

- Hollow Cathode Plasma Source

- Plasma Etching System

- Sintering Presses

- Wet Process & Plating Tool

- Vacuum Chamber

- Electron Beam & Photo Resist

- Deposition Materials

iZERO – In Line Automated

The iZERO encapsulates the unique value of M2-Automation’s technology, contained within a fully flexible, scalable, and highly automated production environment. Without the need to change or reprogram the entire setting during production, the remote-controlled software handles a variety of different products and protocols with ease.

From a few dozen to several thousand targets produced per day, this in-line-production microarray-spotter system reduces the changeover time to a minimum, while maximizing its productive capacity. This makes it the obvious choice to spot your future!

The iZERO can operate all Microdispensers from the M2-Family.

Category: Micro-Nano Dispenser

Description

Key Features

- Supports all dispenser types

- Built-in Windows PC

- Database connection

- Washing and drying station

- Head camera for in-line QC

- 2D or 3D droplet imaging

- Cooling/heating of source area

- HEPA filter system with flow control

- De-ionizer

- Dual-active feed through transfer system

- Orbital shaker for source plates

- On-the-fly dispensing

- µm Z-level distance sensor

- Analytical balance for volume control

- Complete customizations available

Scalable

Starting with a single iZERO unit, M2-Automation’s extendable production line is able to address all needs, ranging from an early pilot phase to automated, well-engineered production.

Reel-to-Reel Applications

The iZERO architecture allows for pass-through of materials to be spotted. This can be from a conveyor belt, or from a reel.

A common reel-to-reel application is for the production of multiplex lateral-flow devices. A multi-channel print head can spot the membrane at varying speeds.

Other applications include spotting on flexible circuits, such as those used in wearable sensors.