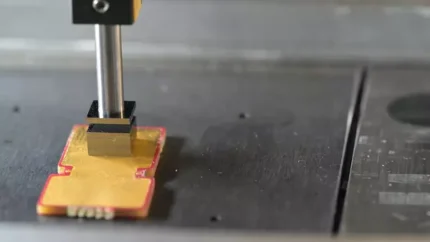

- Bonder & Flip Chip

- Atmospheric Plasma Cleaner

- Vacuum Plasma Cleaner

- Spin Rinse Dryer

- Dispensing & Micro/Nano Printing System

- Lithography Process Systems

- Diffusion and LPCVD Furnaces

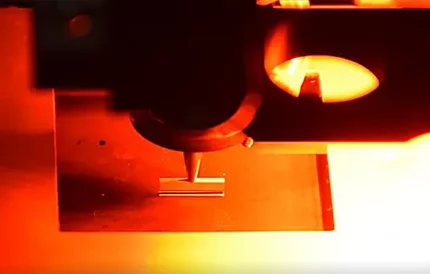

- Rapid Thermal Processing & Annealing

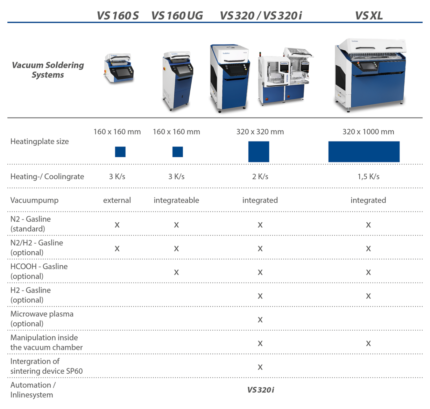

- Vacuum Soldering Systems

- Parylene Coating System

- Deposition System

- Hollow Cathode Plasma Source

- Plasma Etching System

- Sintering Presses

- Wet Process & Plating Tool

- Vacuum Chamber

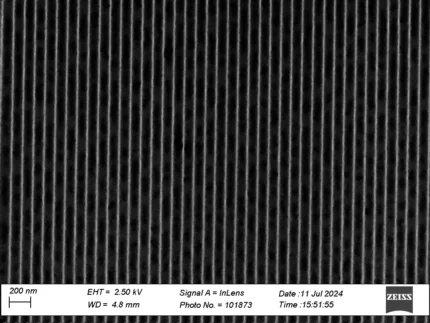

- Electron Beam & Photo Resist

- Deposition Materials

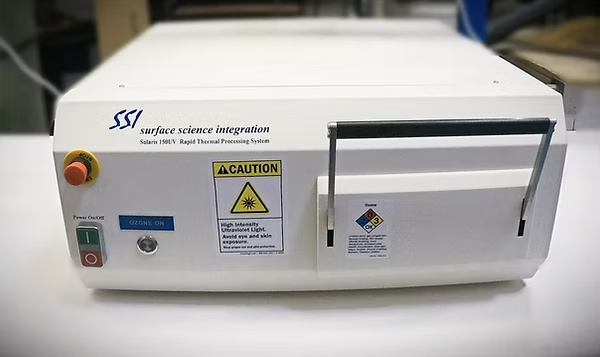

SOLARIS 150mm UV RTP

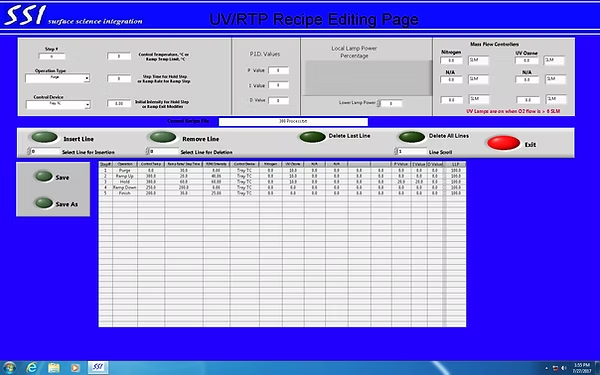

Main Features:

-

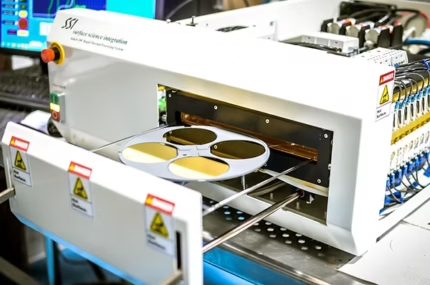

Wafer handling: Manual loading of wafer into the oven, single wafer processing

-

Wafer sizes: 2″, 3″, 4″, 5″, 6″

-

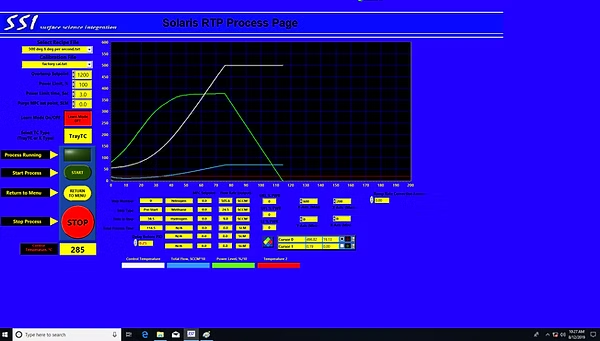

Ramp up rate: 1-150°C per second, user-controllable.

-

Recommended steady state duration: Unlimited, dependent on Temp & cooling

-

Ramp down rate: Temperature Dependent, max 150°C per second.

-

Recommended steady state temperature range: RT – 1200°C

-

Temperature accuracy: +1.78°C total errors

-

Thermocouple temperature accuracy: +1.1°C

-

Temperature repeatability: +2°C or better at Steady State

-

Temperature uniformity: +2.5°C or better across a 6″ (150 mm) wafer at 1150°C.

-

For a titanium silicidation process, no more than 4% increase in non-uniformity

during the first anneal at 650°C to 700°C.

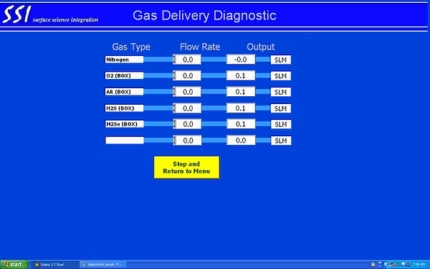

Description

Overview

The Solaris 150UV is a standalone unit or an added option for the Solaris 150 RTP System.

Applications

The Solaris RTP system is a versatile tool that is useful for many applications:

- Pre Gate Oxidation Cleaning

- Pre-Epi Cleaning

- Photoresist Descum

- Growth of Sacrificial Oxides

- Bond Pad Cleaning

- Cleaning of Critical Surfaces

- Hydrocarbon Removal

- High Temperature UV/Ozone Densification