- Bonder & Flip Chip

- Atmospheric Plasma Cleaner

- Vacuum Plasma Cleaner

- Spin Rinse Dryer

- Dispensing & Micro/Nano Printing System

- Lithography Process Systems

- Diffusion and LPCVD Furnaces

- Rapid Thermal Processing & Annealing

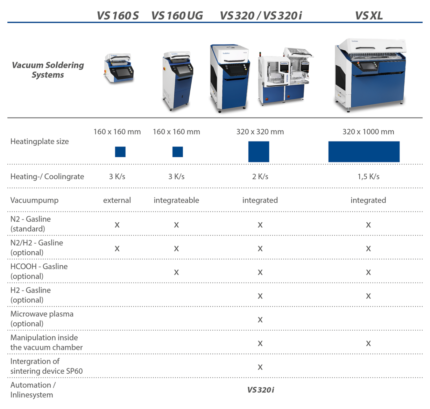

- Vacuum Soldering Systems

- Parylene Coating System

- Deposition System

- Hollow Cathode Plasma Source

- Plasma Etching System

- Sintering Presses

- Wet Process & Plating Tool

- Vacuum Chamber

- Electron Beam & Photo Resist

- Deposition Materials

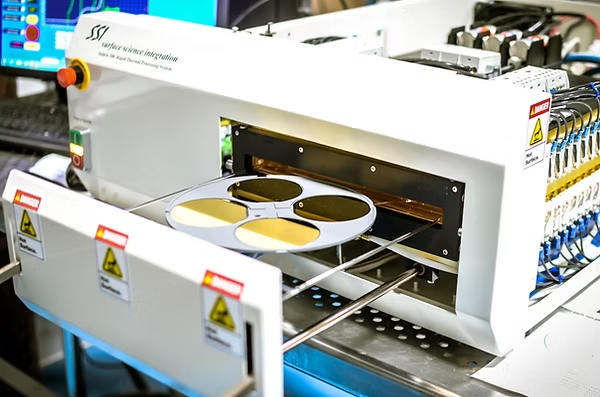

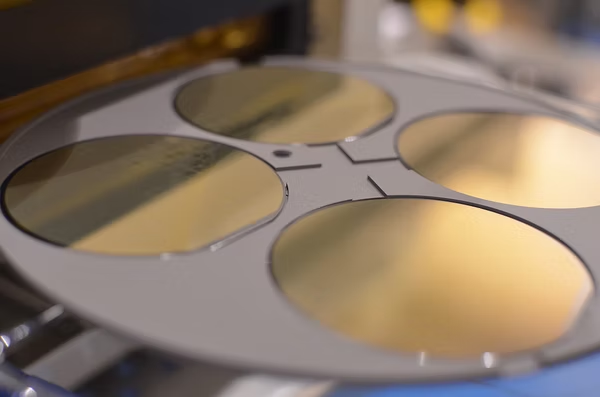

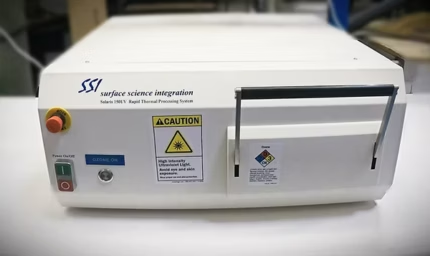

SOLARIS 200mm RTP

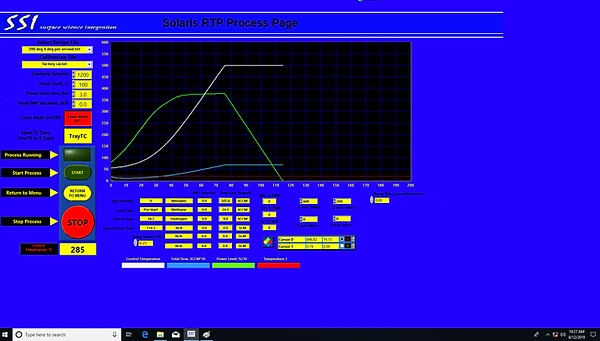

Main Features:

-

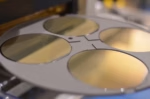

Wafer handling: Manual loading of wafer into the oven, single wafer processing

-

Wafer sizes: 2″, 3″, 4″,5″,6″,8″

-

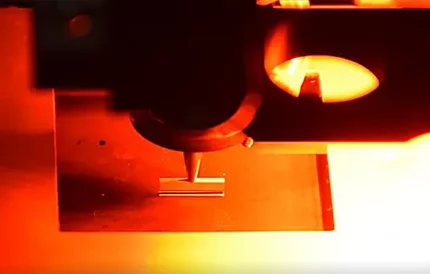

Ramp up rate: 1-150°C per second, user-controllable.

-

Recommended steady state duration: Unlimited, dependent on Temp & cooling

-

Ramp down rate: Temperature Dependent, max 150°C per second.

-

Recommended steady state temperature range: RT – 1200°C

-

Temperature accuracy: +1.78°C total errors

-

Thermocouple temperature accuracy: +1.1°C

-

Temperature repeatability: +2°C or better at Steady State

-

For a titanium silicidation process, no more than 4% increase in non-uniformity

during the first anneal at 650°C to 700°C.

Description

Overview

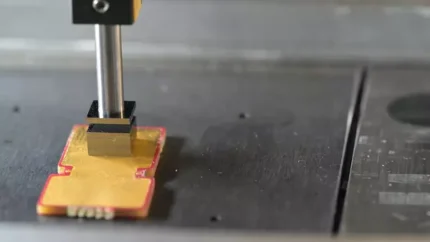

Rapid thermal annealing furnaces offer a wide range of applications such as annealing for silicon and compound semiconductor wafers (RTA), rapid thermal oxidation (RTO), rapid thermal nitriding (RTN), rapid thermal diffusion from a spin-on dopant, crystallization, contact alloying, etc..

The Solaris 200 is a manual loading RTP system built typically for the R&D.

The Solaris uses a unique PID process controller that ensures accurate temperature stability and uniformity. The system can accommodate 6 interlocked MFCs for gas mixing and forming gas processing. The Solaris is designed for silicon implant annealing and monitoring and compound semiconductor implant activation and ohmic alloying.

This System has state of the art options available and is customizable by the end user on purchase. We work with the buyer on every additional feature needed to have a final product that will meet the laboratory demands of the modern scientist. If you are interested in these customizable options please contact a sales representative in your area.

Applications

The Solaris RTP system is a versatile tool that is useful for many applications:

-

Ion Implant Activation

-

Polysilicon Annealing

-

Oxide Reflow

-

Silicide Formation

-

Contact Alloying

-

Oxidation and Nitridation

-

GaAs Processing