- Bonder & Flip Chip

- Atmospheric Plasma Cleaner

- Vacuum Plasma Cleaner

- Spin Rinse Dryer

- Dispensing & Micro/Nano Printing System

- Lithography Process Systems

- Diffusion and LPCVD Furnaces

- Rapid Thermal Processing & Annealing

- Vacuum Soldering Systems

- Parylene Coating System

- Deposition System

- Hollow Cathode Plasma Source

- Plasma Etching System

- Sintering Presses

- Wet Process & Plating Tool

- Vacuum Chamber

- Electron Beam & Photo Resist

- Deposition Materials

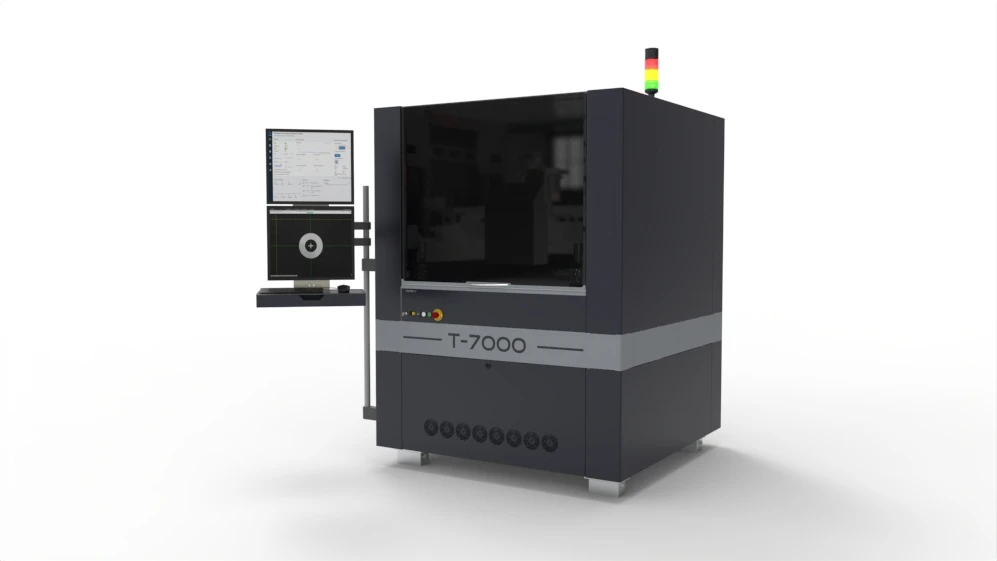

T-7000

The T-7000 machine platform has been developed for use in nanoelectronics and optoelectronics due to its precision. As is standard at Tresky, the bonder platform is based on granite, so that the highest possible precision can be guaranteed for optical components such as VCSELs, lasers, photodiodes, IR sensors or for the development of quantum technologies.

Category: Die Bonder Plat Forms

Description

Leader in Micro-Assembly

Technological miniaturisation and functional integration in microelectronics and optoelectronics are essential for future-oriented product innovations. Micro-assembly and assembly and connection technology play a crucial role in the realization of these technological innovations in new and marketable products.

We have developed the T-7000 to successfully realize these requirements. The platform offers sub-micron placement accuracy, a travel range of 500 x 700 mm and a bonding head with minimum bonding forces of up to 0.01 N. On customer request, the bonding force range can be optionally increased to 100 N, 300 N or 500 N.

This model covers all common bonding technologies.

Technical Data

| Working Area with Wafer Table | 500 mm x 700 mm |

| Possible Wafer Sizes | up to 8″ (ring & frame) |

| Travelling Range Z-axis | 100 mm |

| Tool Rotation Max. | up to 360° |

| Bond Force Range | 0.01 N – up to 300 N * |

| Axis Speed | up to 2.0 m/sec |

| Positioning Accuracy | < 1.0 μm @ 3 sigma |

| Axis Resolution | XYZ: 0.001 μm, theta: 0.005° |

| Min/Max. Chip Size | smaller than 0.05 mm |

| Acceleration | up to 2.5 G |

Product highlights

- Manual mode

- Multichip capable

- Post-bond inspection

- Software-programmed temperature control

- Wafer mapping

- OCR

- Traceability

- MES

- Automated dispensing needle calibration

- Customised splitting

- Scrubbing

- Various image recognition

- Bonding in cavities (15 mm)

- Preform punching

Modules & Options

- Air-suspended bond head

- Vibration feeder

- Wafer handling system

- Stamping module

- Component feeders

- Formic Acid Module

- Wafer table with DIE ejector

- UV indexer

- WRGB ring light

- Heating plates (up to 450°C; ΔT ramps up to 60 K/s)

- Inert gas

- Formic acid module

- Automatic tool change

- Various dispensing technologies

- Stamping unit

- Tool heating

- Various feeder widths

- Uplooking camera

- ID scanner

- DIE flipping unit

- Heated inert gas

- Automatic wafer change

- Magazine feeder

- Inline production

Bonding Solutions

- Epoxy Bonder

- UV Bonder

- Ultrasonic Bonder

- Thermocompression Bonder

- Sinter Bonder

- Flip Chip Bonder

- Eutectic Bonder

- 3D Bonder

- Photonics Bonder