- Bonder & Flip Chip

- Atmospheric Plasma Cleaner

- Vacuum Plasma Cleaner

- Spin Rinse Dryer

- Dispensing & Micro/Nano Printing System

- Lithography Process Systems

- Diffusion and LPCVD Furnaces

- Rapid Thermal Processing & Annealing

- Vacuum Soldering Systems

- Parylene Coating System

- Deposition System

- Hollow Cathode Plasma Source

- Plasma Etching System

- Sintering Presses

- Wet Process & Plating Tool

- Vacuum Chamber

- Electron Beam & Photo Resist

- Deposition Materials

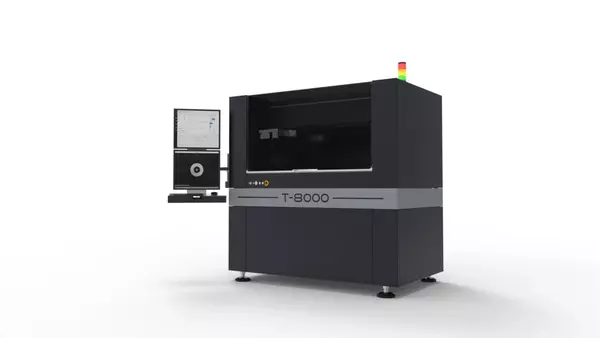

T-8000-G

The T-8000-G DIE bonder is the result of continuous engineering development and offers a larger working area in which 12-inch wafers can be processed. The bonding system combines precision with versatility and speed based on a generously sized granite gantry that allows for maximum accuracy. Thus, the T-8000-G is designed for current and future challenges.

Category: Die Bonder Plat Forms

Description

From Prototype to Production

Based on the solid granite chassis, equipped with linear motors and high-resolution direct measuring systems, the machine offers the largest working range within the product portfolio as well as the best bonding performance in the market. In addition, the T-8000-G is compatible with numerous existing as well as custom-made options and offers the most versatile process possibilities. The bonder can handle any application in assembly and connection technology and combines precision, versatility and speed. Due to its flexibility and modularity, the T-8000-G can be used for prototyping as well as for series production. The manual mode enables fast bonding results without programming.

This model covers all common bonding technologies.

Technical Data

| Travel Range with Wafer | 590 mm x 560 mm |

| Wafer Sizes | 2” – 12” (ring & frame) |

| Travelling Range w/o Wafer | 740 mm x 560 mm |

| Z-Movement | 120 mm |

| Chip Rotation max. | up to 360° |

| Bond Force Range | 0.01 N – bis zu 100 N * |

| Axis Speed | up to 1.8 m/sec |

| Positioning Accuracy | 2.5 μm @ 3 sigma |

| Axis Resolution | XYZ: 0.001 μm, theta: 0.005° |

| Min/Max. Chip Size | smaller than 0.05 mm |