- Bonder & Flip Chip

- Atmospheric Plasma Cleaner

- Vacuum Plasma Cleaner

- Spin Rinse Dryer

- Dispensing & Micro/Nano Printing System

- Lithography Process Systems

- Diffusion and LPCVD Furnaces

- Rapid Thermal Processing & Annealing

- Vacuum Soldering Systems

- Parylene Coating System

- Deposition System

- Hollow Cathode Plasma Source

- Plasma Etching System

- Sintering Presses

- Wet Process & Plating Tool

- Vacuum Chamber

- Electron Beam & Photo Resist

- Deposition Materials

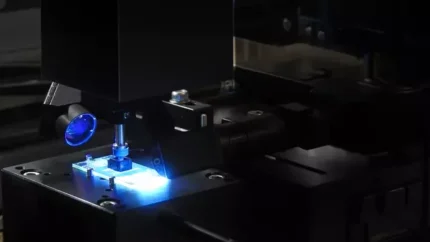

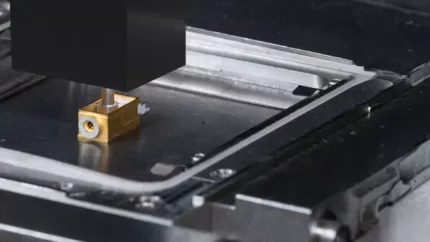

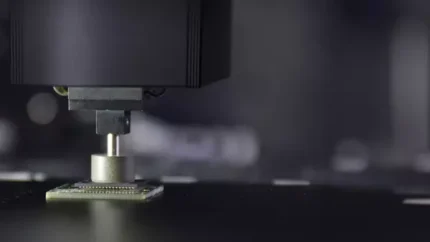

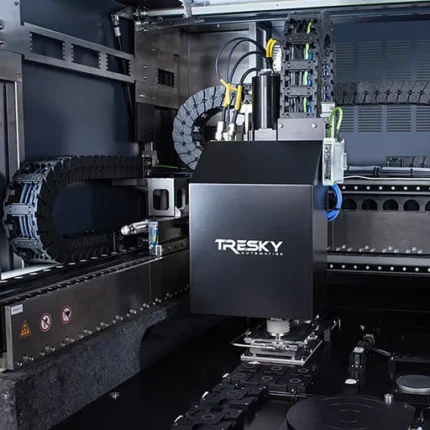

Ultrasonic Bonder

Tresky’s Ultrasonic Bonder allows materials to be bonded together without the use of adhesives, screws or other mechanical fasteners. The process uses ultrasonic vibrations to melt and then reliably bond the two materials to be joined

Category: Die Bonder

Tags: die bonder, temperature sensitive bond, ultrasonic bonder

Description

High-Precision Connection Technology for Temperature-Sensitive Components

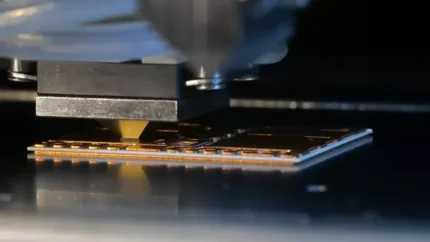

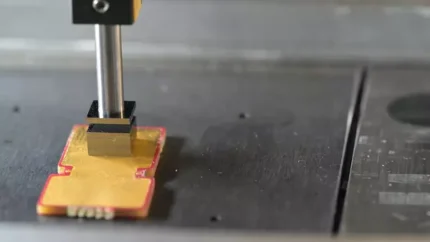

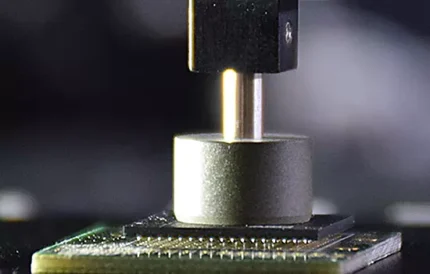

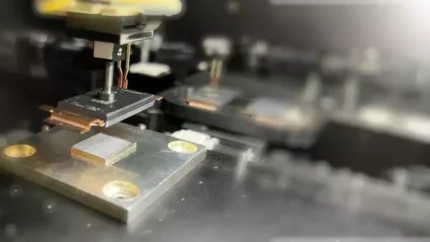

Ultrasonic bonding is a bonding process for producing an electrically conductive and mechanically material bond between a chip and a substrate. In the friction welding process, pressure (bonding force) and ultrasonic vibration (friction) are used to create an electrically conductive contact. The ultrasonic energy is applied when the chip is placed by the bonding head.

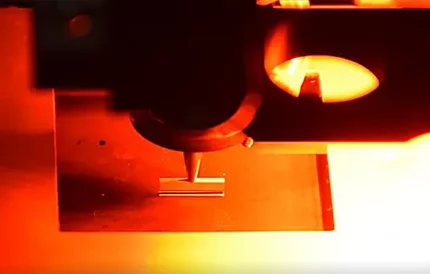

Temperature-sensitive components or components that are difficult to heat can be bonded in this way by ultrasonic bonding. If heat is also used as a support, this is known as thermosonic bonding. The effectiveness of ultrasonic bonding is determined by several variable parameters, such as bonding force, ultrasonic power, frequency and bonding time, which play a crucial role in ensuring the quality and reliability of the connections made.

Added Value

Cycle Time Optimization

Ultrasonic bonding allows shorter bonding times to be implemented due to the elimination of preheating time.

High Power Density

Ultrasonic bonding enables the production of high-performance components with high power density.

Low Thermal Load

The process generates a lower thermal load compared to conventional bonding methods. This can reduce material stress on semiconductor components.

Reliability

Connections made by ultrasonic bonding are reliable and have low failure rates. This is critical to the quality and durability of electronic components.

Versatility

Ultrasonic bonding can be used with a wide range of materials and chip types, increasing its versatility in various applications.

No Joining Materials

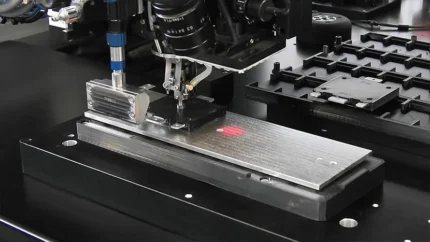

For example, in radio frequency (RF) applications, adhesive or solder joints are often ruled out because they radically degrade signal quality. Ultrasonic bonding creates a direct connection without a connecting layer.

Miniaturization

Ultrasonic bonding enables the miniaturization of electronic components and thus contributes to the development of compact and powerful electronic devices.

Variable Parameters for Ultrasonic Bonding are

- Bond force (pressure)

- Ultrasonic power (energy)

- Frequency (vibration)

- Bonding time

You can find more information here

Reviews (0)

Be the first to review “Ultrasonic Bonder” Cancel reply

Reviews

There are no reviews yet.