- Bonder & Flip Chip

- Atmospheric Plasma Cleaner

- Vacuum Plasma Cleaner

- Spin Rinse Dryer

- Dispensing & Micro/Nano Printing System

- Lithography Process Systems

- Diffusion and LPCVD Furnaces

- Rapid Thermal Processing & Annealing

- Vacuum Soldering Systems

- Parylene Coating System

- Deposition System

- Hollow Cathode Plasma Source

- Plasma Etching System

- Sintering Presses

- Wet Process & Plating Tool

- Vacuum Chamber

- Electron Beam & Photo Resist

- Deposition Materials

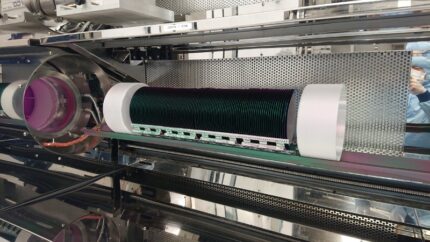

Vertical Thermal Reactors (VTR)

Vertical thermal reactors from Expertech offer production-proven semiconductor diffusion processes. Providing a fully automated diffusion furnace solution with superior uniformity, the VTR7000PLUS has demonstrated world-class performance. VTR systems feature a unique dual-boat design for maximum operation and utilize premium components for reduced contamination in recipe-driven loading and processing technology.

Description

Advantages of VTR Vertical Diffusion Furnaces

A highly automated reactor with robust design features and a small footprint, Expertech’s VTR system is one of the most well-known furnace designs worldwide. The VTR7000PLUS offers exceptional within-wafer and wafer-to-wafer uniformity in atmospheric and LPCVD processes. It is an ideal tool for advanced manufacturing, providing various benefits, including:

- Manufacturing Versatility

- Increased Automation & Throughput

- Optimized Contamination Control

- Reduced Cost-of-Ownership

This production proven semiconductor diffusion furnace design was originated by Silicon Valley Group (SVG) and is now a product line fully owned and supported by Expertech. With over 1000 VTR systems currently in production use worldwide, it continues to maintain a global footprint for vertical furnace systems.

VTR7000PLUS Model Features

The VTR7000PLUS is a fully automated diffusion furnace that offers proven production superiority. Its design can achieve a higher throughput per tube using a dual-boat design, where one boat is in process while the other loads or reloads. Other high-quality features of Expertech’s vertical diffusion furnaces include the following:

- Features a ULPA-filtered Class 1 loading area and electropolished stainless steel surfaces for superior particle control

- Uses a small-volume, ultraclean technology gas panel that is manufactured, tested, and capped in a cleanroom for fewer in-film defects

- Easier and faster process tube maintenance through a mechanized tube removal system

- Using a double-walled process tube to eliminate film particle formation near the loading door for advanced particle control in LPCVD films

- Safety interlocks to protect personnel and equipment

- Easy-to-learn operator interface with optional cell supervisor workstations for central monitoring and recipe control for a bank of up to 8 VTR systems

Engineered with design enhancements for improved maintainability, high reliability, reduced contamination, and the smallest footprint in the industry, the VTR provides valuable cost savings through:

- Low cost per wafer processed

- Low cost to maintain

- Low capital and installation cost

Specifications for VTR Diffusion Furnaces

Recognized as one of the most established vertical furnace systems, the VTR7000PLUS offers exceptional operation and performance specifications for semiconductor diffusion processes. With reliable heating elements, versatile advanced manufacturing processes, a high-quality design, and an ergonomically improved operator interface, Expertech builds vertical diffusion furnaces to meet your production requirements.

VTR Reactor Performance

- Flush mounted – no cleanroom projection

- Width: 37 inches (95 cm)

- Depth: 62 inches (1.57 m)

- Height: 78 inches (1.98 m) in cleanroom wall

- Height: 9 feet 8 inches (2.95 m) in service area

- Service requirement: 4 feet (1.2 m) in rear

- Up to 58 steps per recipe

- Optional Host Supervisor system

- Floppy drive / USB Port

- SEMI Standard cassette type

- Typical diffusion/oxidation: 150 product, test, and filler wafers. Exact load size process dependent.

- Typical LPCVD: 150 product, test, and filler wafers. Exact load size process dependent.

VTR System Operation

- Standard Wafer Size: 150 mm and 200 mm

- Optional Wafer Size: 100 mm and 125 mm

- Low-Temperature Element of 250-600° C

- Mid-Temperature Element of 500-1050° C

- High-Temperature Element of 600-1200° C (Up to 1250° C for > 4 Hours)

- Uniformity: Flat zone, 22.5 in (57 cm)

- Temp Control: ±0.5°C for Process Above 600° C

- Class 1 Laminar Flow, Mirror-Finish 300 Series Stainless Steel Surfaces

- ULPA Filter Tested to 99.9995% of Particles Greater Than 0.12 µm

- Optional <100 PPM O2 Controlled Environment Available

Process Models Available

Atmospheric:

- Wet/Dry Oxidation

- Anneals

- Forming Gas Anneals

- Hydrogen Anneals

- Phosphorus Predeoposition

- POCl3

LPCVD:

- Silicon Nitride (Dual Wall)

- TEOS (Dual Wall)

- Uniform Grain Polysilicon (Amorphous & Uniform Grain, N & P Doped)

- HTO

Reviews (0)

Be the first to review “Vertical Thermal Reactors (VTR)” Cancel reply

Reviews

There are no reviews yet.