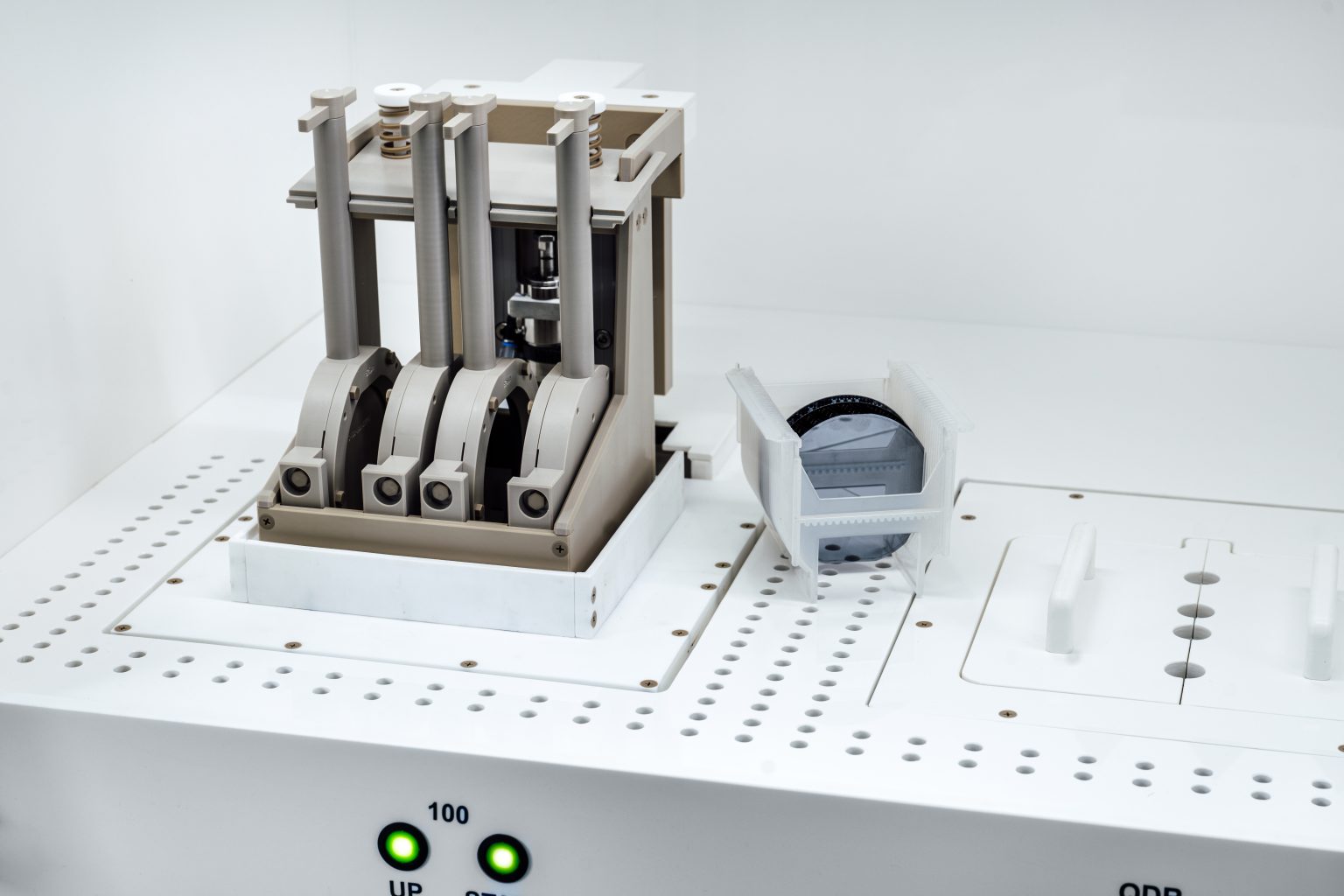

- Bonder & Flip Chip

- Atmospheric Plasma Cleaner

- Vacuum Plasma Cleaner

- Spin Rinse Dryer

- Dispensing & Micro/Nano Printing System

- Lithography Process Systems

- Diffusion and LPCVD Furnaces

- Rapid Thermal Processing & Annealing

- Vacuum Soldering Systems

- Parylene Coating System

- Deposition System

- Hollow Cathode Plasma Source

- Plasma Etching System

- Sintering Presses

- Wet Process & Plating Tool

- Vacuum Chamber

- Electron Beam & Photo Resist

- Deposition Materials

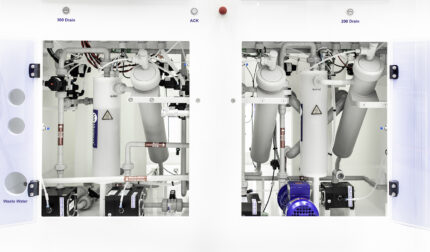

Wet Bench System µCHEM

- Designed for the use in clean room environment, the shell is made of polypropylene or stainless steel for solvent applications

- Suitable for etching application in the field of micro technology and semiconductors

- Heatable Quartz Tank for clean wafer processing

- Additional process cells could be integrated, made of PTFE, PVDF, PP,…

- Circulation and Heating systems

- fire extinguishing on request

- fully automatic processfully automatic chemical drain and dosing on request

- compatible to different wafer size up to 12″, fully automatic handling of the Carriers

Additional components

- Spin coater, Hot plates, Megasonic cleaning systems…

- Rinsing cell or Quick Dump Rinser

- Automation for handling wafer baskets possible

- Customized solutions are possible

MOT Semicon can help you to design specific workflow concepts offering you flexible high grade wet bench solutions.

Category: Wet Process & Plating Tool

Tag: Wet Bench