- Bonder & Flip Chip

- Atmospheric Plasma Cleaner

- Vacuum Plasma Cleaner

- Spin Rinse Dryer

- Dispensing & Micro/Nano Printing System

- Lithography Process Systems

- Diffusion and LPCVD Furnaces

- Rapid Thermal Processing & Annealing

- Vacuum Soldering Systems

- Parylene Coating System

- Deposition System

- Hollow Cathode Plasma Source

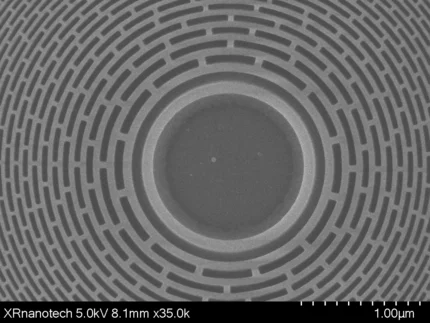

- Plasma Etching System

- Sintering Presses

- Wet Process & Plating Tool

- Vacuum Chamber

- Electron Beam & Photo Resist

- Deposition Materials

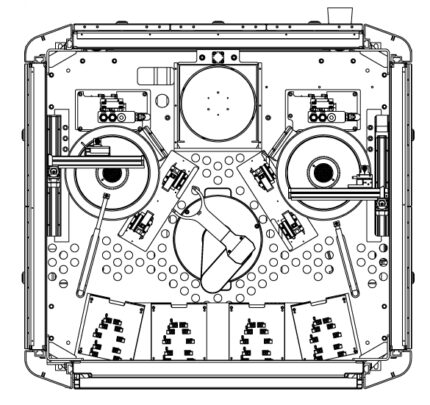

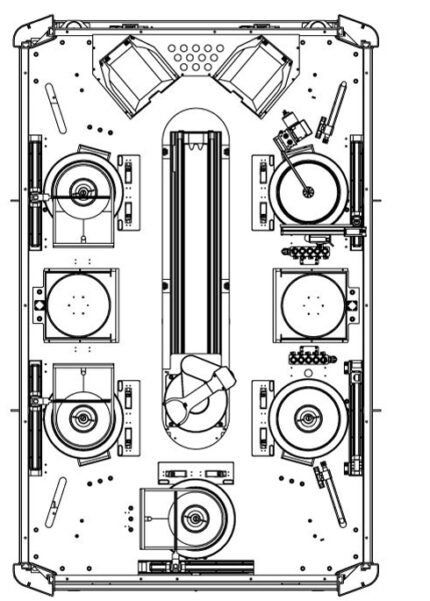

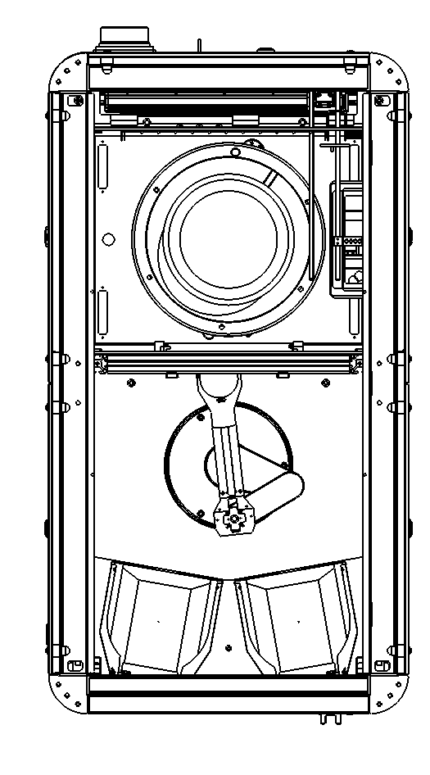

amc 3000 Fully automatic single-wafer processing

Established quality for a wide range of applications up to 300 mm

Our modular spinner is the perfect completion of our series of fully automatic single wafer processing tools. With its substrate size-range between 150 and 300 mm (9” square) offers very flexible applications in coating, lift-off, developing, cleaning, vapor priming and heating of wafers and masks. As always, we focus on our customers´ needs and therefore, every tool may be optimized for either flexible single processes or high throughput. The possibility of FOUamc 3000 P loading via robot or rail system in the cleanroom or plant is just as self-evident as the integration of an optional 300 mm SECS.

Offers the possibility of FOUP loading via robot or rail system, as well as the integration of an optional 300 mm SECS:

- Wafer diameters: 150 mm to 300 mm or 7 x 7” to 9 x 9”

- Up to 2 I/O stations for 150 mm to 200 mm open cassettes or 300 mm FOUP

- Max. 5 individually selectable processing modules

- 1 two link robot handler with single or double end effector

- Outer dimensions W x L: 2082 mm x 2003 mm

Download brochures here.

Category: Lithography Process Systems

Tags: Developer, Etching, Hot plate, Lift off, Lithography, Photo resist, Spin coater, Spray coater

Description

Beneficial highlights:

300 mm SECS/GEM interface: our software is configured to support 300 mm standard SECS/GEM communication or other customized protocols if needed.

Proven amc key features: stands out due to all proven technical features of the other models, as well as the unique user friendly machine design. A genuine through-the-wall installation is possible, just as are flexible machine adjustments and easy maintenance.

Safe: the equipment is designed accordingly to the newest safety rules.

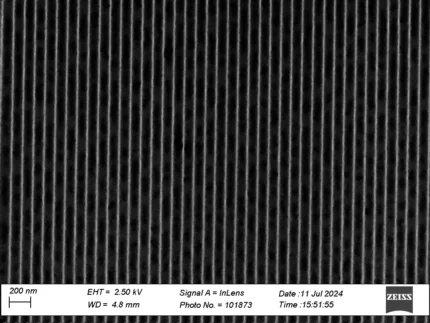

Full process control: each selected process is managed by the relevant module of our comfortable amcoss software complying with Semi-Standard E95-1101. All necessary parameters can be adjusted and will be logged into the softamsPILOT ware.

Unique single-nozzle grip: The innovative positioning arm with single-nozzle grip carries only one nozzle at the time. This avoids

particle build-up caused by friction of rubbing tubes. All nozzles momentarily not required, remain within the nozzle storage with rinse and drip pan, which prevent the tip of the nozzle from drying out and impede delayed dripping onto the substrate.