- Bonder & Flip Chip

- Atmospheric Plasma Cleaner

- Vacuum Plasma Cleaner

- Spin Rinse Dryer

- Dispensing & Micro/Nano Printing System

- Lithography Process Systems

- Diffusion and LPCVD Furnaces

- Rapid Thermal Processing & Annealing

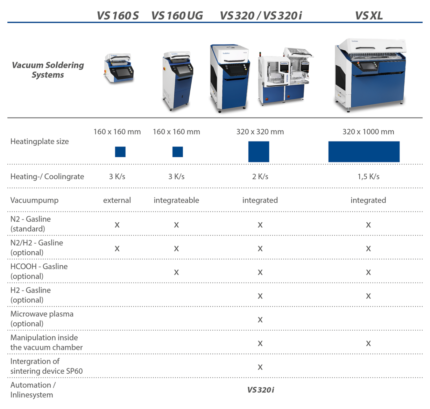

- Vacuum Soldering Systems

- Parylene Coating System

- Deposition System

- Hollow Cathode Plasma Source

- Plasma Etching System

- Sintering Presses

- Wet Process & Plating Tool

- Vacuum Chamber

- Electron Beam & Photo Resist

- Deposition Materials

SU-8_Photo Resist

Category: Electron Beam & Photo Resist

Tags: EBL, Lithography, Photo resist, semiconductor, SU8

Description

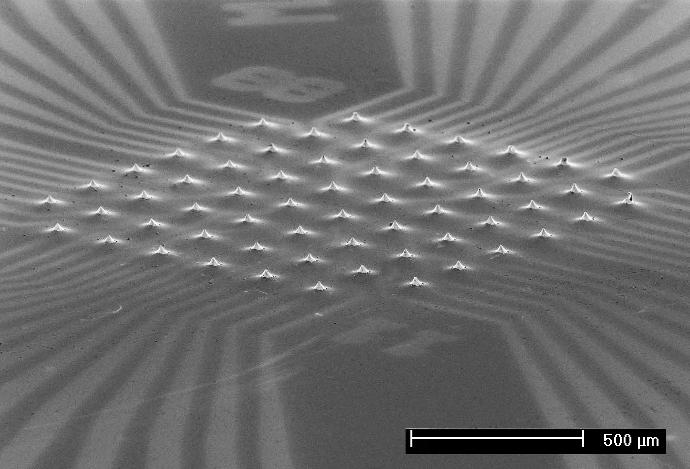

SU-8 (GMXX Series) Photoresist

EM Resist offers a range of classic SU-8 photoresist products ideal for semiconductor applications. Our products are available under various forms and in a range of thicknesses.

Below is a table of our GM10XX products. If you have any specific requirements, please contact us for more information.

| Product | Film Thickness Range | Coating Options |

|---|---|---|

| GM1010 | < 0.2 μm | Spray Coat |

| GM1020 | 0.2 – 0.5 μm | Spin, Spray, Inkjet |

| GM1030 | 0.5 – 1.2 μm | Spin, Spray, Inkjet |

| GM1040 | 0.9 – 3.2 μm | Spin, Spray, Inkjet |

| GM1050 | 3 – 8 μm | Spin, Inkjet |

| GM1060 | 2 – 27 μm | Spin, Inkjet |

| GM1070 | 15 – 200 μm | Spin, Inkjet |

| GM1075 | 100 – 400 μm |

A typical SU-8 process consists of the following steps:

- Substrate preparation

- Spin coating

- Relaxation time to improve the surface uniformity

- Soft-bake

- Exposure to initiate cross-linking

- Post exposure bake

- Development

- Rinse & Dry

- Optional hard bake

For individual processing conditions for each product, please contact us for the relevant datasheets.