- Bonder & Flip Chip

- Atmospheric Plasma Cleaner

- Vacuum Plasma Cleaner

- Spin Rinse Dryer

- Dispensing & Micro/Nano Printing System

- Lithography Process Systems

- Diffusion and LPCVD Furnaces

- Rapid Thermal Processing & Annealing

- Vacuum Soldering Systems

- Parylene Coating System

- Deposition System

- Hollow Cathode Plasma Source

- Plasma Etching System

- Sintering Presses

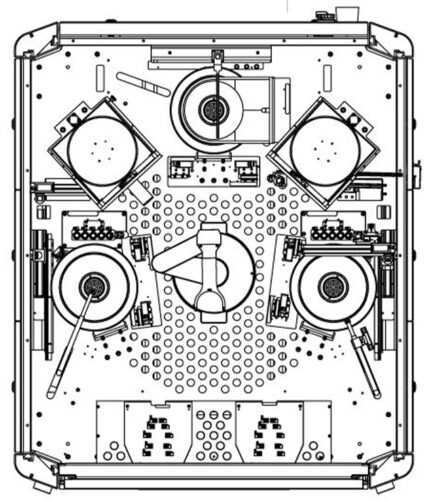

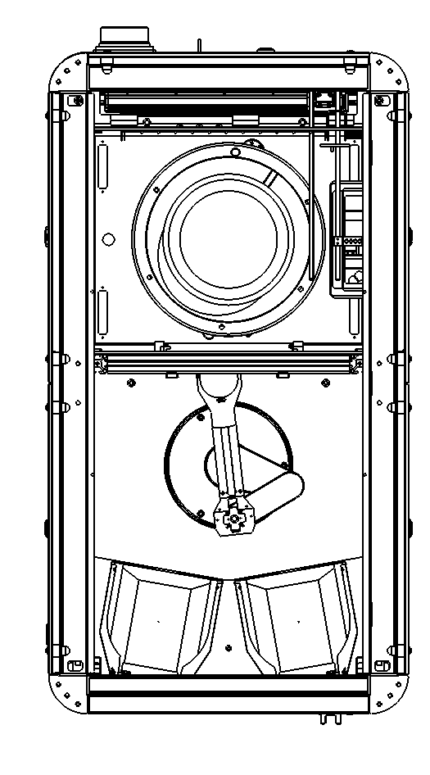

- Wet Process & Plating Tool

- Vacuum Chamber

- Electron Beam & Photo Resist

- Deposition Materials

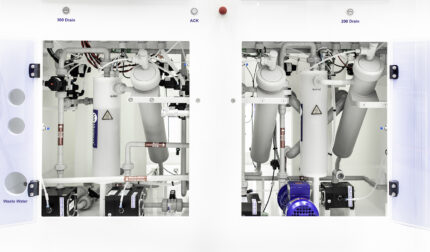

Electrochemical Etch Stop µECES

Electrochemical etch-stop (ECES) is a popular method for bulk micromachining of a p-n junction silicon wafer in MEMS applications.

Bias-voltage dependent etching of silicon in alkaline solutions (KOH, TMAH) is a regular anisotropic etch. Etching stops at passivation potential (PP) due to excess generation of SiO2 on the wafer surface, when reached the n epi layer – this is a local effect contributing to uniformity. ECES allows

- Fabricating membranes with precise thickness control.

- Achieving un-paralleled membrane thickness uniformity usually better +/- 0.8%

- Precise thickness control independent from precise etchant concentration and temperature control

Category: Wet Process & Plating Tool

Tags: Electrochemical etch-stop, Etching, Membrane, MEMS, TMAH