- Bonder & Flip Chip

- Atmospheric Plasma Cleaner

- Vacuum Plasma Cleaner

- Spin Rinse Dryer

- Dispensing & Micro/Nano Printing System

- Lithography Process Systems

- Diffusion and LPCVD Furnaces

- Rapid Thermal Processing & Annealing

- Vacuum Soldering Systems

- Parylene Coating System

- Deposition System

- Hollow Cathode Plasma Source

- Plasma Etching System

- Sintering Presses

- Wet Process & Plating Tool

- Vacuum Chamber

- Electron Beam & Photo Resist

- Deposition Materials

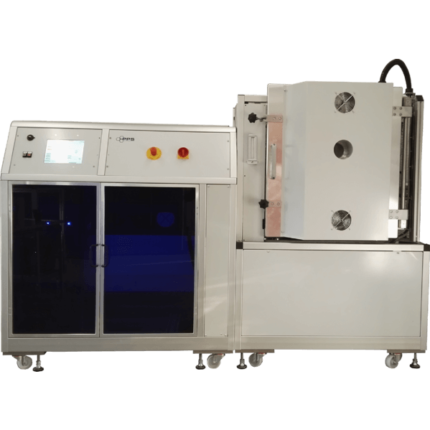

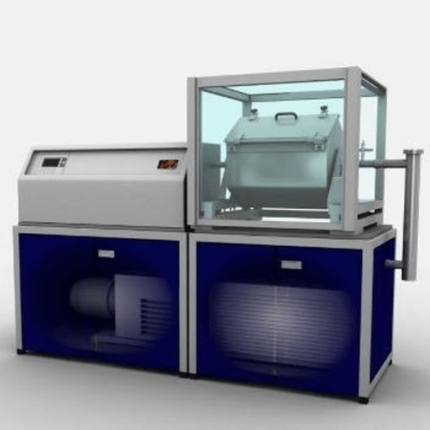

Labcoater Series 300

Labcoater for laboratory and production facilities.

Optimized for smaller companies and production teams.

Optional equipment makes this labcoater a very versatile machine with a variable process chamber volume, starting at 25l.

Built-in plasma source.

Also available as cleanroom version.

Choice of 4 different volumes.

Categories: All, Parylene Coating System

Description

Versatile system, optimized for laboratory work with build-in plasma source for surface pre-treatment

|

Dimensions:

|

L: 1220mm W: 1050mm H: 1920mm

|

|

Weight:

|

110 KG

|

|

Volume:

|

25 / 35 / 40 / 80 Liter

|

|

Process chamber:

|

300mm Ø H: 300mm (25 Liter), 300mm Ø / H: 350mm (35 Liter), 450mm Ø, H: 500mm (80) Liter

|

|

Plasma source:

|

2,45GHz, 600 Watt

|

|

Inclusive:

|

1 gas channel (gas distribution system inside the process chamber), up to 3 channels possible

|

|

Cooling system:

|

4 liter (electromechanical Cool-trap)

|

|

Vacuum connection:

|

DIN 40 ISO-KF

|

|

Venting:

|

electromagnetic solenoid valve

|

|

Pump system:

|

50m³/h

|

|

Electrical connection:

|

3/N/PE AC 50Hz 400 V / 240 V, max. 8.5 KW

|