- Bonder & Flip Chip

- Atmospheric Plasma Cleaner

- Vacuum Plasma Cleaner

- Spin Rinse Dryer

- Dispensing & Micro/Nano Printing System

- Lithography Process Systems

- Diffusion and LPCVD Furnaces

- Rapid Thermal Processing & Annealing

- Vacuum Soldering Systems

- Parylene Coating System

- Deposition System

- Hollow Cathode Plasma Source

- Plasma Etching System

- Sintering Presses

- Wet Process & Plating Tool

- Vacuum Chamber

- Electron Beam & Photo Resist

- Deposition Materials

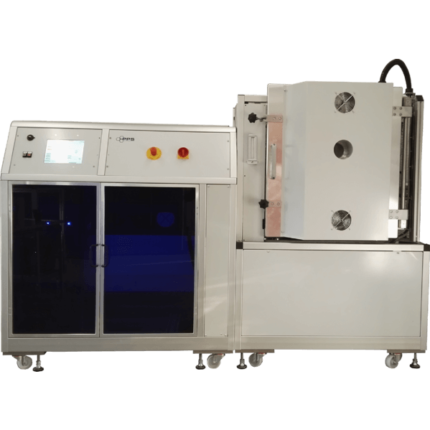

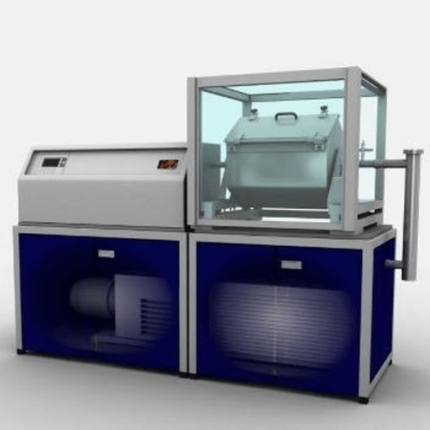

Series 3000 Cleanroom System

Developed for applications which have to be executed in clean rooms.

Modular assembly and variable chamber sizes.

Countless options like turntables or different holders for substrates.

Loading of the process chamber takes place from the clean room.

Unloading through the airlock door in the gray room.

Categories: All, Parylene Coating System

Description

|

Dimensions:

|

L: 2095mm W: 800 H: 1450mm

|

|

Weight:

|

~ 300 KG

|

|

Volume:

|

140 / 200 / 300 litres

|

|

Process chamber:

|

500mm Ø H: 700mm (140 Liter), 600mm Ø / H: 700mm (200 Liter), 700mm Ø, H: 800mm (300 Liter)

|

|

Plasma source:

|

2,45GHz, 1200 Watt

|

|

Inclusive:

|

1 gas channel (gas distribution system inside the process chamber), up to 3 channels possible

|

|

Cooling system:

|

8 liter (electromechanical Cool-trap)

|

|

Vacuum connection:

|

DIN 40 ISO-KF

|

|

Venting:

|

electromagnetic solenoid valve

|

|

Pump system:

|

75m³/h

|

|

Electrical connection:

|

3/N/PE AC 50Hz 400 V / 240 V, max. 8.5 KW

|