- Bonder & Flip Chip

- Atmospheric Plasma Cleaner

- Vacuum Plasma Cleaner

- Spin Rinse Dryer

- Dispensing & Micro/Nano Printing System

- Lithography Process Systems

- Diffusion and LPCVD Furnaces

- Rapid Thermal Processing & Annealing

- Vacuum Soldering Systems

- Parylene Coating System

- Deposition System

- Hollow Cathode Plasma Source

- Plasma Etching System

- Sintering Presses

- Wet Process & Plating Tool

- Vacuum Chamber

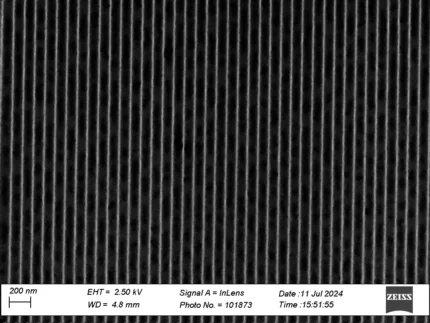

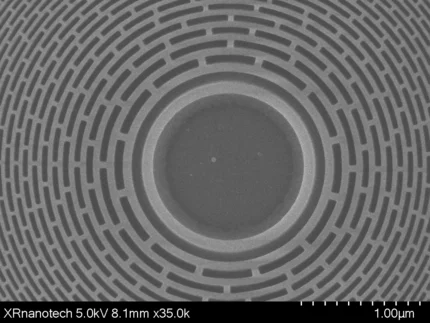

- Electron Beam & Photo Resist

- Deposition Materials

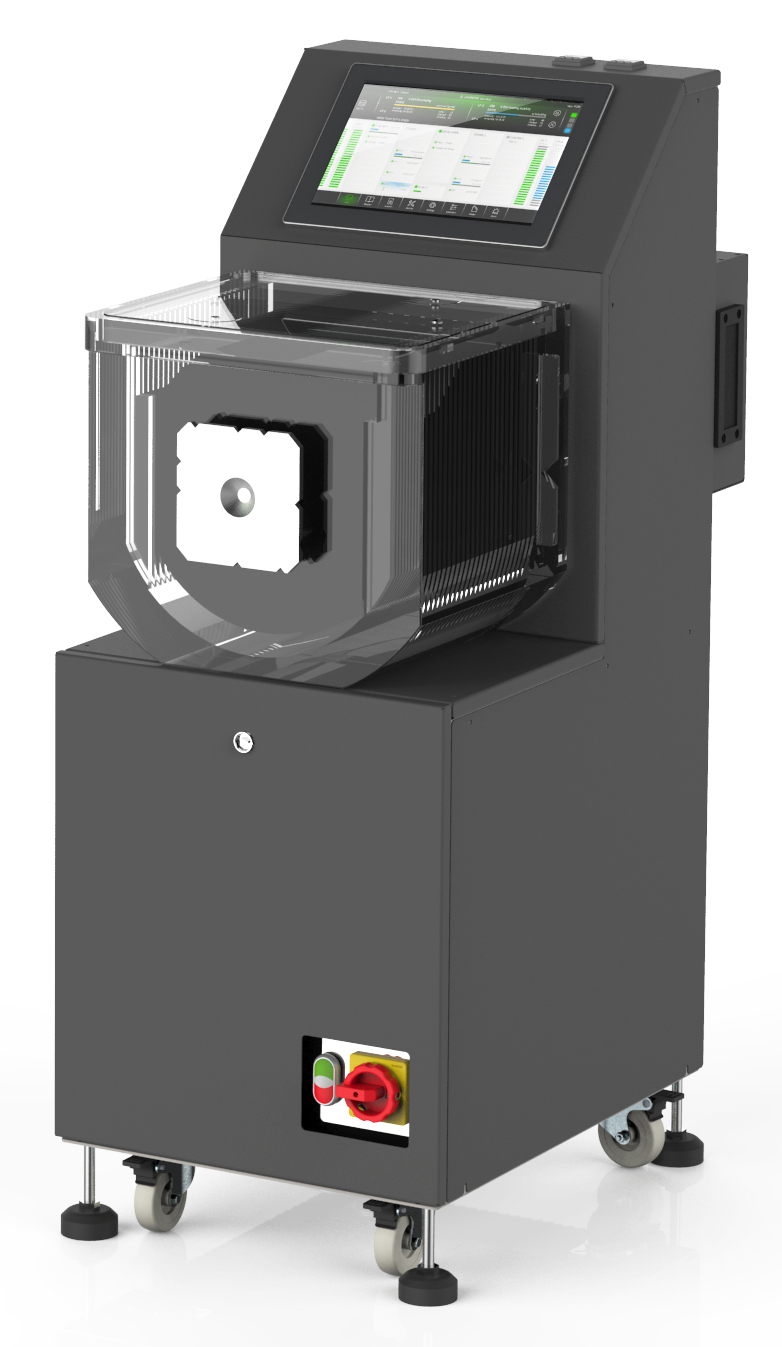

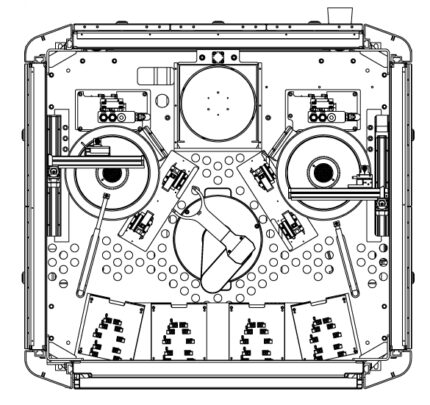

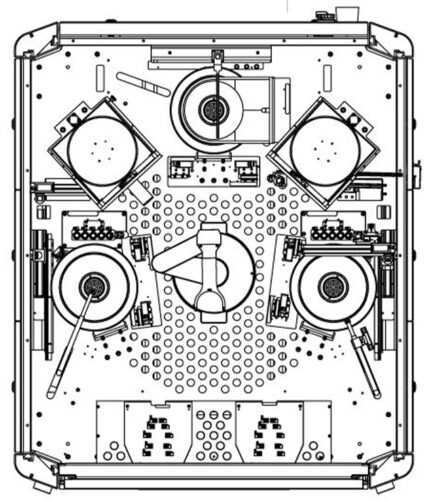

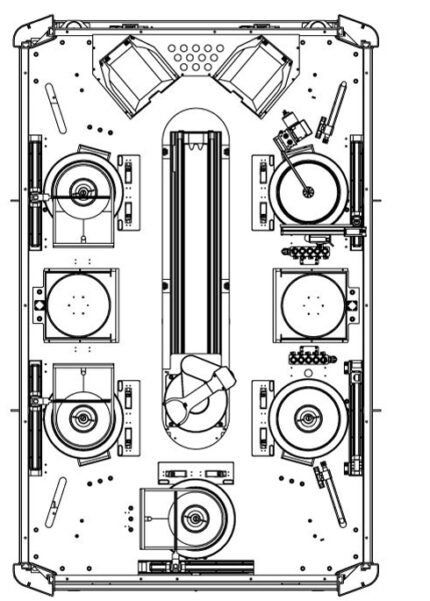

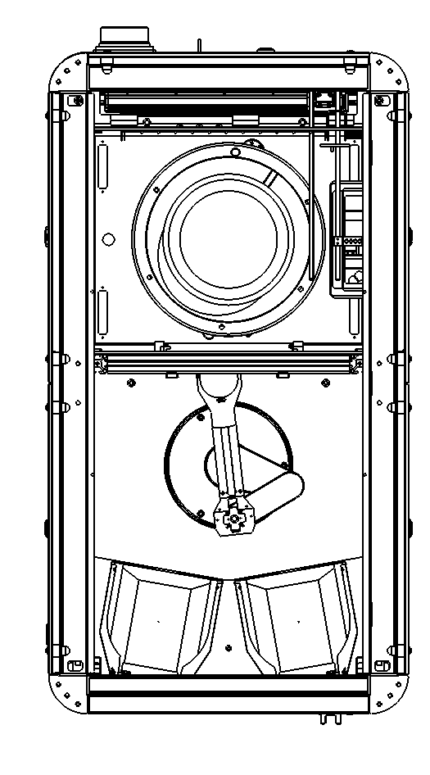

amr 200/300 Semi-automatic single wafer processing

Our semi-automatic equipment – the modular, highly flexible amr stand-alone spinner and our individually configurable amt tabletop hotplate – is of great benefit for R&D laboratories and institutions with small-lot production and single processing steps within the treatment of a variety of substrate specifications.

Our amcoss amr series for coating, developing, cleaning, lift-off, vapor priming, etching and heating of individual substrates is a completely modular system and perfectly adapted to the requirements of single- and small batch series production. The control unit, consisting of the control system with the ams PILOT software, may be flexibly combined according to customer needs and specific process requirements, with one or more selected processing units. Every unit holds one processing module (coater, developer, cleaner, lift-off, etcher, hot-/coolplate, vapor priming hotplate or media module). Therefore, our customers can individually compose their personal amr equipment. Depending on the wafer diameters that will have to be processed, the units will be fitted with different processing modules of varying sizes. As a consequence there are two amr types varying in size with, however, the same dimensions:

amr 200 – for wafer types 2“ to 200 mm in diameter, as well as Small Pieces

amr 300 – for wafer types 2“ to 300 mm in diameter, as well as Small Pieces

Download brochures here.

Category: Lithography Process Systems

Tags: Developer, Etching, Hot plate, Lift off, Lithography, Photo resist, Spin coater, Spray coater, Wet process

Description

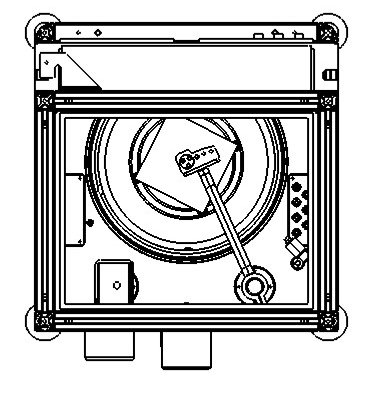

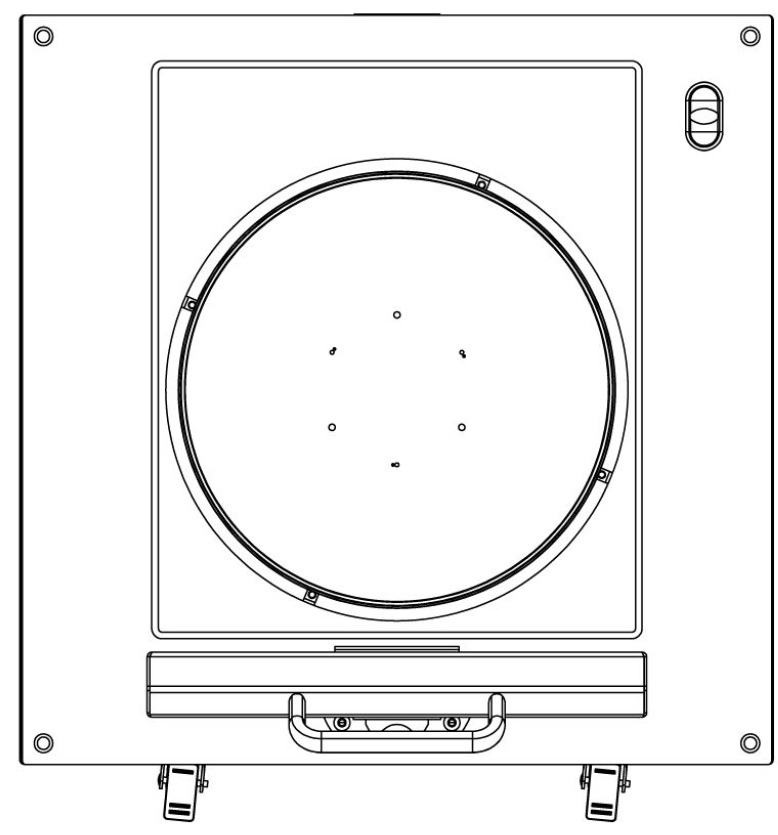

amr control unit

Control system with ams PILOT software for control and easy operability of all processing units connected.

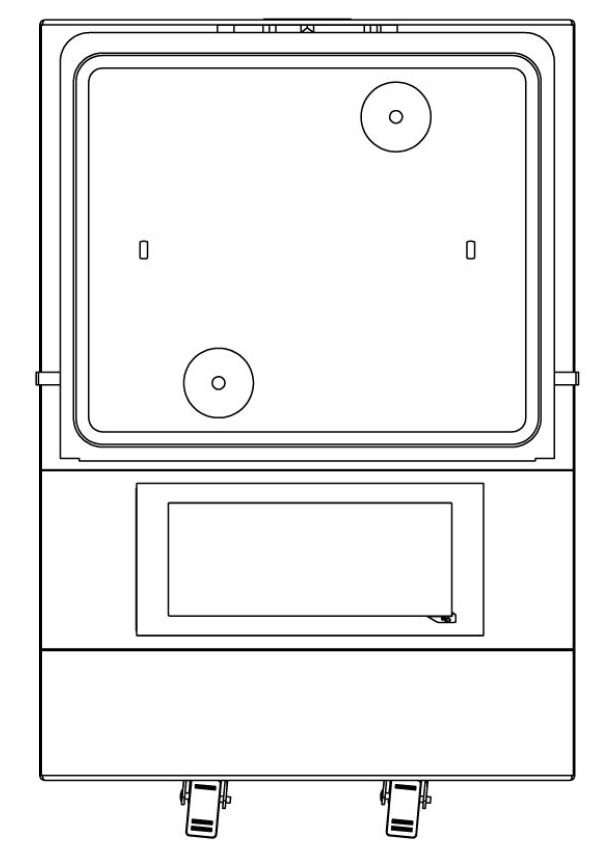

Standard unit

- Outer dimensions L x W: 600 x 450 mm

- 12” colour-touchscreen with IPC

- Carrier placement area for easy loading and unloading of substrates

- Comfortable access to components inside the housing

- Recipes can be transferred from or into amcoss amc equipment

Extra-slim control unit

- Outer dimensions L x W: 600 x 200 mm

- Exceptionally slim for minimum space requirements

- 12” touch screen on moveable arm

- One process module can be connected and controlled

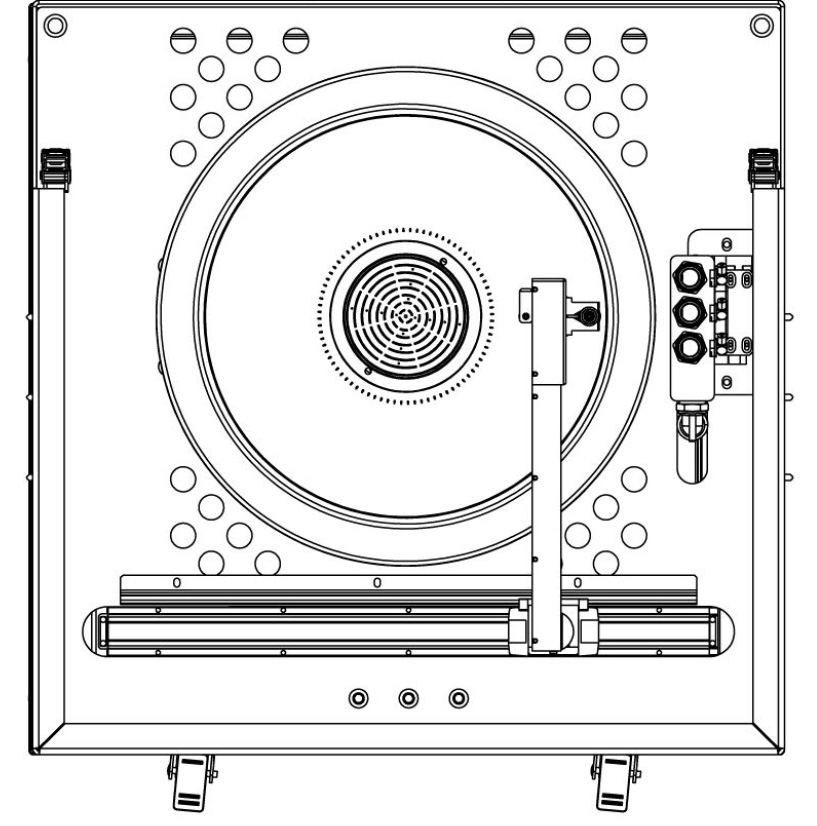

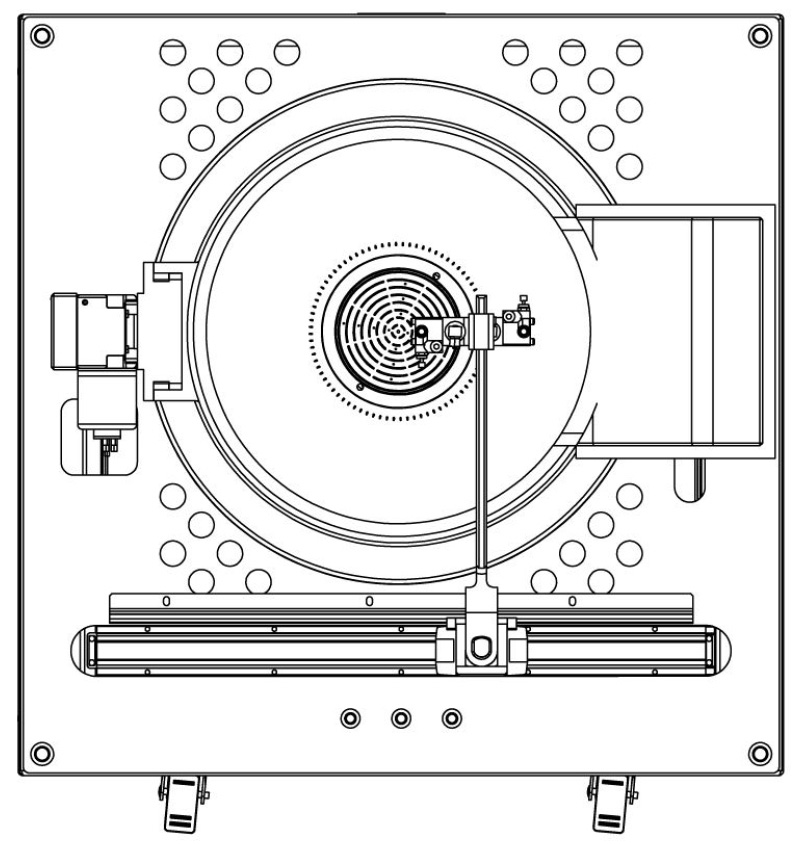

Coater unit

- Outer dimensions L x W: 600 x 600 mm

- Positive- & negative-coating

- SU8 coating

- PMMA coating

- Spray coating

- Thick-resist coating

Developer unit

- Outer dimensions L x W: 600 x 600 mm

- Puddle developing

- Spray developing,

- Developing with TMAH, KOH & solvents

Lift-off/etching unit

- Outer dimensions L x W: 600 x 600 mm

- Standard metal-lift-off with NMP, DMSO

- Resource-saving metal-lift-off with DMSO Megasonic

- Solvent strip

- FEOL etching

- BEOL etching

- Metal etching

Cleaner unit

- Outer dimensions L x W: 600 x 600 mm

- Post CMP cleaning

- RCA cleaning

- Frontside, backside and edge bevel cleaning

- TSV cleaning